Shiva’s Night Out

Shivaratri – the Night of Shiva – is observed on the fourteenth night of the dark fortnight of the lunar month of Magh/Falgun (February/March). This is the night Lord Shiva is said to have performed the dance of primordial creation, preservation and destruction – Tandava Nritya (one of the many myths associated with the festival).

Therein lies the allegory of Shivaratri, which over “time”, “hinduization” and “interpretations,” have subdued the real essence of the spiritual “Shiva-Shakti” (male-female principle) culture, traces of which can be found in every religion and civilization.

Shivaratri is Nepal’s best known mela (religious fair) that draws tens of thousands of pilgrims and – more importantly – the sadhus (holy men) at Pashupatinath (Lord of the Animal Life) Temple, one of the Subcontinent’s four great Shiva shrines, in Kathmandu.

During Shivaratri, hundreds of sadhus come from all across the Subcontinent to lounge beside their dhuni (bonfire) in the extensive Pashupatinath complex. They represent various sampradayas (sects) and play a major role in the spiritual and social life of South Asia.

Very little is known about their origin, but historians and anthropologists have thus far concluded they represent the world’s oldest spiritual paths in the history of humankind. They are part of an ascetic tradition, renouncing their worldly lives to follow the path of self-denial.

Demonstrating a core of inner strength, sadhus astound onlookers with their agility in various yoga postures and smoke ganja (marijuana) to help gain spiritual attainment, which has been a sort of sacrament among Shaivites (devotees of Shiva) for centuries. They take turns with the chillum and circle around the dhuni, making an akhara.

The scene continues until the great midnight, as pilgrims join to share their prasad.

Source : exposure-2010-21

JUVET LANDSCAPE HOTEL

If you really want to get away from it all, try the Juvet Landscape Hotel near Alsted in west Norway. Tourists are drawn to this remote spot by the Reinheimen National Park, a sublime tableau of mountains and forests, with a famous waterfall set in a deep ravine.

Knut Slinning established a hotel here by renovating old farm buildings near the ravine. He also commissioned the Oslo-based partnership of Jensen & Skodvin to provide new accommodation on the site. Now in their late forties, Jan Olav Jensen and Børre Skodvin were highly commended in the AR Awards for Emerging Architecture for a church at Mortensrud (AR December 2002). Connecting with nature but still unsentimentally of its time, their work draws deeply on the Norwegian modernist tradition of Sverre Fehn (see page 24). More recently, a convent on the Norwegian island of Tautra astutely explores the interaction between the man-made, spiritual and natural worlds.

In terms of form and programme, the hotel is a much simpler proposition, but with a thoughtful twist. Rather than construct a large, intrusive single building, the architects hive off the individual rooms into seven self-contained cabins dispersed around the thickly wooded site. Careful orientation and space planning ensures that none of the cabins directly overlook each other. Each has its own view of the landscape so, to some extent, guests can pretend that it’s just them and the great outdoors.

Despite the bucolic setting, Jensen & Skodvin forsakes folksy rusticity in favour of a more minimal, Miesian aesthetic. Each cabin is an exquisitely simple single-storey box clad in strips of Norwegian larch. As they are intended only for use during the summer, walls are uninsulated. Floor-to-ceiling glazing is set against slim frames of standard steel profiles and stepped edges extend the external layer of glass to the corners. Cabins accommodate two people and, though similar in size, each has a slightly varied living room and sleeping area, with a bathroom contained in a narrow leg plugged in to the main volume. The crisply detailed larch and glass containers form a taut counterpoint to the dreamy luxuriance of the landscape.

To impact lightly on the site, cabins sit on platforms supported by 40mm diameter steel foundation rods drilled into the rock. This causes minimal disruption to the existing topography and vegetation, a fact that the architects are keen to emphasise, both as a practical response to the site and as a contribution to wider notions of sustainable building. ‘Conservation of topography is an aspect of sustainability that deserves attention,’ explains Jensen, dismayed at how most construction usually involves the obliteration or modification of the existing terrain. ‘Conserving the site is a way to respect the fact that nature precedes and succeeds man,’ says Skodvin. ‘Observation of the topography also highlights the irregularities of the natural site, explaining both itself and its context with more power.’

cabins touch the ground lightly and defer to the landscape

Cabins are clad in thin strips of larch

within touching distance

A TAUT COUNTERPOINT To tHE DREAMY

LUXURIANCE OF THE LANDSCAPE

How to design hygienic toilets for 2.6bn people

A child dies every 15 seconds from contaminated water. Four years ago, Swedish architect and academic Anders Wilhelmson began a pioneering project addressing the lack of adequate sanitation, experienced by 2.6 billion people globally, which spreads deadly diseases among the most impoverished of the world’s population.

Wilhelmson’s brainchild is the Peepoo bag, a single-use biodegradable sack which functions as a portable personal toilet. The bag is lined with a layer of gauze to avoid contact with bodily fluids and, once sealed, remains odour-free for up to 24 hours. It is a sanitation solution that eliminates the need for water, reducing the spread of lethal pathogens contained within excrement. It is also a welcome alternative for women and children who are at risk if they go out to use public toilets at night.

A professor of architecture, Wilhelmson taught a course on growth and city development at Sweden’s Royal University College of Fine Arts. ‘When you’re out studying cities,’ he explains, ‘you realise that about 60 per cent of them are slums or informal settlements. Everything is difficult in those areas. But housing they could make, electricity is easy to get, water you can get – but sanitation seemed to be very difficult to manage, even on an individual basis. Nobody cares. So I said to myself: “Why are architects concerned about buildings when sanitation is more important? Why not pursue this?”’

After conceiving the idea in 2005, Wilhelmson put together a team of experts comprising engineers, bioplastics experts and industrial designers to investigate the possibilities. The result is a product that is self-sanitising and can act as fertiliser after use. Due to a thin lining of urea inside the bag, all pathogens are broken down and the bag becomes a source of nutrients for the soil. Encouraged by the findings of a year’s worth of research, Wilhelmson founded the company Peepoople AB, before applying for a patent in 2007. Field tests began in 2008 and Peepoople began promoting the product through the likes of the World Health Organisation and the UN Secretary-General’s Advisory Board on Water & Sanitation (UNSGAB).

he project’s initial launch coincided with the UN-declared International Year of Sanitation in 2008, an effort to solve the sanitation crisis and achieve the Millennium Development Goal on environmental sustainability, which entails halving the number of people without access to basic sanitation by 2015. ‘That seems very unrealistic today,’ says Wilhelmson. ‘We are modest about what we believe we can achieve. But in the long run, we’re talking hundreds of millions.’

Field tests were successfully carried out in December in Kibera (pictured above), Africa’s largest slum, which houses one million people in around two square miles of Nairobi, Kenya. 300 people used the Peepoo bag for a month before completing questionnaires and attending focus groups. Peepoople is now in talks to establish long-term funding and production is expected to begin by the end of this year.

‘As architects, we have to tackle problems,’ explains Wilhelmson. ‘Architecture is engagement. And you could take a share of your time to be engaged in major problems.’ Is it that not enough people care? ‘We need to care more, that’s for sure,’ he replies. Ultimately, Wilhelmson believes that the Western world has a lot to learn, in the event we face our own crises in years to come. ‘Since we are engaged in these areas, we learn a lot which we can use for tackling problems at home. Their need could be the answer to our problems as well.’

Alumunium Structures # What Is Alumunium?

This chapter does not deal with the origins of aluminum or how it is refined from bauxite, although the ruin satLes Bauxde Provence in southern France are certainly worth a visit. There is an ingot of aluminum in the museum at La Citadelle des Baux as atribute to the metal that is produced from the nearby red rock, which the geologist Berthier dubbed ‘‘bauxite’’ in honor of this ancient fortress in1821. The ruins of the medieval stronghold, though, are the real attraction. We’ll defer to Fodor’s and Frommer’s on the travel tips, and to Sharpona discussion of the history, mining, and production of aluminum. Our purpose in this chapter is to discuss aluminum’s place in the families of structural metals.

We include aluminum with steel and reinforced concrete as a metal-based material of construction. While our basis for this grouping may not be immediately obvious, it becomes more apparent when considered in an historical context.

2.1 METAL IN CONSTRUCTION

We include aluminum with steel and reinforced concrete as a metal based material construction. While our basis for this grouping may not be immediately obvious, it becomes more apparent when considered in an historical context.

Prior to the development of commercially viable methods of producing iron, almost all construction consisted of gravity structures. From the pyramids of the pharoahs to the neoclassical architecture of Napoleonic Europe, builders stacked stones in such a way that the dead load of the stone pile maintained a compressive state of force on each component of the structure (see Figure 2.1). The development of methods to mass-produce iron, in addition to spawning the Industrial Revolution in the nineteenth century, resulted in iron becoming commercially available as a material of construction. Architecture was then freed from the limitations of the stone pile by structural components that could be utilized in tension as well as compression. American architect Frank Lloyd Wright observed that with the availability of iron as a construction material, ‘‘the architect is no longer hampered by the stone beam of the Greeks or the stone arch of the Romans.’’ Early applications of this new design freedom were the great iron and glass railway stations of the Victorian era. Builders have been pursuing improvements to the iron beam

ever since.

An inherent drawback to building with iron as compared to the old stone pile is the propensity of iron to deteriorate by oxidation. Much of the effort to improve the iron beam has focused on this problem. One response has been to cover iron structures with a protective coating.

Fig 2.1 Pont du Gard in southern France. An aqueduct that

the ancient Romans built by skillfully stacking stones.

The term coating may be taken as a reference to paint, but it is really much broader than that. What is reinforced concrete, for example, but steel with a very thick and brittle oating? Because concrete is brittle, it tends to crack and expose the steel reinforcing bars to corrosion. One of the functions served by prestressing or osttensioning is to apply a compressive force to the concrete in order to keep these cracks from opening.

While one approach has been to apply coatings to prevent metal from rusting, another has been to develop metals that inherently don’t rust. Rust may be roughly defined as that dull reddish-brown stuff that shiny steel becomes as it oxidizes. Thus, the designation of ‘‘stainless’’ to those iron-based metals that have sufficient chromium content to prohibit rusting of the base metal in atmospheric service. The ‘‘stain’’ that is presented is the rust stain. Stainless steel must have been a term that originated in someone’s marketing department. The term confers a quality of having all the positive attributes of steel but none of the drawbacks.

If we were to apply a similar marketing strategy to aluminum, we might call it ‘‘light stainless steel.’’ After all, it prevents the rust stain as surely as stainless steel does, and it weighs only about one-third as much. Engineers who regard aluminum as an alien material may be more favorably disposed toward ‘‘light stainless steel.’’

For the past century and a half, then, structural engineers have relied on metals to impart tension-carrying capability to structural components. Technical development during that time has included improvement in the properties of the metals available for construction. One of the tasks of designers is to determine which metal best suits a given application.

2.2 MANY METALS FROM WHICH TO CHOOSE

Structural metals are often referred to in the singular sense, such as ‘‘steel,’’ ‘‘stainless steel,’’ or ‘‘aluminum,’’ but, in fact, each of these labels applies to a family of metals. The label indicates the primary alloying element, and individual alloys are then defined by the amounts of other elements contained, such as carbon, nickel, chromium, and manganese. The properties of an alloy are determined by the proportions of these alloying elements, just as the characteristics of a dessert are dependent on the relative amounts of each ingredient in the recipe. For example, when you mix pumpkin, spices, sugar, salt, eggs, and milk in the proper quantities, you make a pumpkin pie filling. By adding flour and adjusting the proportions, you can make pumpkin bread. Substituting shortening for the pumpkin and molasses for the milk yields ginger cookies. Each adjustment of the recipe results in a different dessert. Whereas the addition of flour can turn pie filling into bread, adding enough chromium to steel makes it stainless steel.

2.3 WHEN TO CHOOSE ALUMINUM

2.3.1 Introduction

Today aluminum suffers from a malady similar to that which afflicted tomatoes in the eighteenth century: many people fail to consider it out of superstition and ignorance. Whereas Europeans shunned tomatoes for fear that they were poisonous, engineers seem to avoid aluminum for equally unfounded reasons today.

One myth is that aluminum is not sufficiently strong to serve as a structural metal. The fact is that the most common aluminum structural alloy, 6061-T6, has a minimum yield strength of 35 ksi [240 MPa], which is almost equal to that of A36 steel. This strength, coupled with its light weight (about one-third that of steel), makes aluminum particularly advantageous for structural applications where dead load is a concern. Its high strength-to-weight ratio has favored the use of aluminum in such diverse applications as bridge rehabilitation (Figure 2.2), large clear-span dome roofs (Figure 2.3), and fire truck booms. In each case, the reduced dead load, as compared to conventional materials, allows a higher live or service load.

Aluminum is inherently corrosion-resistant. Carbon steel, on the other hand, has a tendency to self-destruct over time by virtue of the continual conversion of the base metal to iron oxide, commonly known as rust. Although iron has given oxidation a bad name, not all metal oxides lead to progressive deterioration. Stainless steel, as noted previously, acquires its feature of being rust-resistant by the addition of chromium to the alloy mixture. The chromium oxidizes on the surface of the metal, forming a thin transparent film. This chromium oxide film is passive and stable, and it seals the base metal from exposure to the atmosphere, thereby precluding further oxidation. Should this film be scraped away or otherwise damaged, it is self-healing in that the chromium exposed by the damage will oxidize to form a new film.

Figure 2.2 Installation of an aluminum deck on aluminum beams

for the Smithfield Street Bridge in Pittsburgh, Pennsylvania

Aluminum alloys are also rendered corrosion-resistant by the formation of a protective oxide film, but in the case of aluminum it is the oxide of the base metal itself that has this characteristic. A transparent layer of aluminum oxide forms on the surface of aluminum almost immediately upon exposure to the atmosphere. The next discussion on coatings describes how color can be introduced to this oxide film by the anodizing process, which can also be used to develop a thicker protective layer than one that would occur naturally.

Corrosion-prone materials are particularly problematic when used in applications where it is difficult or impossible to maintain their protective coating. The contacting faces of a bolted connection or the bars embedded in reinforced concrete are examples of steel that, once placed in a structure, are not accessible for future inspection or maintenance. Inaccessibility, in addition to preventing repair of the coating, may also prevent detection of coating failure. Such locations as the seam of a bolted connection or a crack in concrete tend to be places where moisture or other agents of corrosion collect.

Furthermore, aluminum is often used without any finish coating or painting. The cost of the initial painting alone may result in steel being more expensive than aluminum, depending on the quality of coating that is specified. Coatings also have to be maintained and periodically replaced. In addition to the direct cost of painting, increasing environmental and worker safety concerns are associated with painting and paint preparation practices. The costs of maintaining steel, then, give aluminum a further advantage in life-cycle cost.

Fig 2.3 Aerial view of a pair of aluminum space frames covered

with mill finish (uncoated) aluminum sheeting

2.3.2 Factors to Consider

Clearly, structural performance is a major factor in the selection of structural materials. Properties that affect the performance of certain types of structural members are summarized in Table 2.1.

For example, the strength of a stocky compression member is a function of the yield strength of the metal, while the strength of a slender compression member depends on the modulus of elasticity. Since the yield strength of aluminum alloys is frequently comparable to those of common carbon and stainless steels, aluminum is very competitive with these materials when the application is for a stocky column. Conversely, since aluminum’s modulus of elasticity is about one-third that of steel’s, aluminum is less likely to be competitive for slender columns.

Strength is not the only factor, however. An example is corrosion resistance, as we noted above. Additional factors, such as ease of fabrication (extrudability and weldability), stiffness (modulus of elasticity), ductility (elongation), weight (density), fatigue strength, and cost are compared for three common alloys of aluminum, carbon steel, and stainless steel in Table 2.2.

TABLE 2.1 Properties That Affect Structural Performance of Metals

| Structural Performance of | Property |

| tensile members columns (compression members) beams (bending members) fasteners welded connections | yield strength, ultimate strength, notch yield strength, modulus of elasticity yield strength, ultimate strength, modulus ultimate strength ultimate strength of filler alloy; ultimate strength of heat-affected base metal |

TABLE 2.2 Comparing Common Structural Shapes and Grades of Three Metals

While cost is critical, comparisons based on cost per unit weight or unit volume are misleading because of the different strengths, densities, and other properties of the materials. Averaged over all types of structures, aluminum components usually weigh about one-half that of carbon steel or stainless steel members. Given this and assigning carbon steel a relative cost index of 1 results in an aluminum cost index of 2.0 and stainless cost index of 4.7. If initial cost were the only consideration and carbon steel could be used without coatings, only carbon steel would be used. But, of course, other factors come into play, such as operation and maintenance costs over the life of the structure. Also, in specific applications, the rule of thumb that an aluminum component

weighs one-half that of a steel member doesn’t always hold true. For example, an aluminum component might weigh considerably less when a corrosion allowance must be added to the steel. In other cases, the low material cost of steel is offset by higher fabrication costs, such as applications requiring complex cross sections (for example, curtainwall mullions). In such cases, the cost of steel is much more than just the material cost since the part must be machined, cold-formed, or welded to create the final shape, while the costs of aluminum fabrication are almost nonexistent (the material cost includes the cost to extrude the part to its final shape).

Because of stainless steel’s high cost, it is used only when weight is not a consideration and finish and weldability are. In fact, when stainless steel is used in lieu of aluminum, the reason is often only concern about welding aluminum.

The families of structural metals, and the individual alloys within each, then, offer a wide range of choices for designers. Each recipe or alloy designation results in certain characteristics that serve specific purposes. When corrosion resistance, a high strength-to-weight ratio, and ease of fabrication are significant design parameters, aluminum alloys merit serious consideration.

Garage Doors

Builders Are Head-Over-Heels

For Overhead Door

Overhead Door was ranked by readers as the #1 garage door manufacturer in brand familiarity, brand used in past two years, brand used most and quality, according to BUILDER magazine’s annual Brand Use survey. Since the company’s invention of the original overhead garage door in 1921 and its first garage door opener in 1926, Overhead Door and its family of brands (which include Genie® and Wayne-Dalton®) has remained at the forefront of the garage door industry, making it a true Brand Leader.

“We are very honored that builders know and choose our brand first,” said Preston Bowen, Senior Vice President of Sales and Marketing. “A satisfied customer is our ultimate goal.”

The Right Garage Door For Your Project Overhead Door offers builders a wide array of design options, materials and price points from which to choose…

“Green Doors”

EcoBuilt® offers the right combination of beautiful designs, environmentally-friendly construction and value with eight primary designs and many customizable options. Choose from the EcoBuilt® Verde Collection™ or the EcoBuilt® Traditional Panel Collection™.

“Steel Doors”

- The Banner Collection® of steel doors are designed for smooth, quiet operation, featuring pinch-resistant panels.

- Thermacore® is the premiere line of steel insulated doors that feature a metal-foam-metal sandwich construction to provide the highest R-values available.

- The Courtyard Collection® are custom steel doors that provide the exceptional good looks of a “custom wood” garage door combined with the value and long lasting durability of an insulated door.

“Wood Doors”

- Signature™ Wood Doors are crafted from exotic meranti hardwood.

- Ranch House® offers classic designs and custom wood doors made to your specification.

No matter what your project calls for, Overhead Door has the perfect garage door system to fit your needs. That’s why builders across the country overwhelmingly choose Overhead Door for their projects.

For more information visit

www.OverheadDoor.com

Entry Doors

Innovation Keeps Therma-Tru Doors

At The Top Of The Market

It was a bold innovation when Therma-Tru® introduced an entryway door that looked as beautiful as wood but performed with the durability of steel over 25 years ago. The company revolutionized the industry by creating the first fiberglass exterior door.

Today, Therma-Tru offers its customers a nearly unlimited selection of door styles and decorative glass and has become the leading manufacturer of fiberglass and steel exterior door systems. That’s why Therma-Tru is again ranked by pros as the brand they use most.

“Since we introduced the first fiberglass entry door, the Fiber-Classic®, we have continued to invest in new technologies that are aimed at providing our customers with reliable products that are easy to buy, install and will make a lasting impression,” says David Randich, president of Therma-Tru Doors.

New Products Increase Curb Appeal And Energy-Efficiency

This year’s additions feature beautiful door styles designed to match many different home styles, as well as new options and features all created to increase both curb appeal and energy efficiency. The new glass designs are crafted to be on consumer trend and appeal to a wide range of customers. Therma-Tru also enhanced its warranty on Smooth-Star® products so that now all Therma-Tru fiberglass products carry a Limited Lifetime warranty.

New products for 2010:

• 8-foot Fiber-Classic® Mahogany Collection™

• New fiberglass 20-minute fire doors

• New Falling WaterTM glass design for Fiber-Classic® Mahogany and Oak Collections™, Smooth-Star® and steel entry doors

• Concorde™ and Saratoga™ glass designs are now available in both the Fiber-Classic® Mahogany and Oak Collections™

• Low-E glass is now standard on Classic-Craft® fiberglass doors

• Contoured grilles between glass (GBG)

• Craftsman style full-lite patio doors

For more information on

Therma-Tru Doors, visit

www.thermatru.com

Brick Siding

Affordability

Today’s buyers are looking for a solid value in the homes they purchase. With Boral®, you can offer customers the ultimate in exterior cladding value. Homes built with clay brick are virtually maintenance free, requiring no paint or siding touch ups and are impervious to rot and mold. A solid brick veneer provides a strong barrier to most weathering conditions for a safe, worry-free home.

Style And Comfort

Style and beauty are very important to homebuyers. Boral’s 23 manufacturing plants produce a wide range of color and texture choices to please any palette preference. Only Boral offers specialty products like 17th Century® brick and PastelCote®. And clay brick helps insulate against outside noise, so every home you build with Boral brick will be quieter, which is particularly relevant when square footage and lot sizes are reduced.

Energy Efficiency

Boral’s products are energy efficient. Clay brick provides thermal mass, which slows and controls the transfer of temperature differentials from the exterior to the interior of the home. In addition, brick is installed with a one-inch pocket of air space that insulates the home from temperature and moisture transfer. As a result, your buyers will enjoy lower energy bills throughout the year.

Boral® Pavers will never fade

Sustainability

Boral leads the brick industry in its commitment to sustainable manufacturing. The company is a founding member of the Climate Registry, a sponsor of Earthcraft House, and a member of the United States Green Building Council (USGBC). Boral’s facilities harvest clay locally; manufacture to strict guidelines for emissions reduction and elimination, and with its wide network of plants, the company can supply most markets with locally manufactured products.

Boral’s manufacturing facility in Terre Haute, Indiana has earned Leadership in Energy and Environmental Design (LEED) Certification. The company’s two newest plants are some of the first brick manufacturing plants to fuel brick kilns using captured methane from local landfills. Boral also has a three-tier strategy for the use of renewable fuels throughout its plant network.

Boral® offers over 150 brick colors and textures.

For complete information on Boral’s products, services and commitment to sustainability visit www.boralbricks.com . While there, you can review the Harris Interactive Siding Study, which proves beyond a shadow of a doubt that homebuyers prefer brick.

INTERIOR DESIGN EVOLVES IN OMAN

AWARENESS ON INTERIOR DESIGNING IS SLOWLY CATCHING UP IN THE SULTANATE AMONG DIFFERENT SECTIONS. A. HARIKUMAR ANALYSES THE LATEST TRENDS

Interior design in the Sultanate is beginning to evolve. Here as well as in the most parts of the world, in the past, interior design at initial stage meant interior decoration. It was confined to the selection of colours and materials only. However, interior design today describes a professional approach to interiors that places more emphasis on basic planning and functional design than decoration.

But the situation is fast changing. Of late, the science of interior design is gaining acceptance in Oman. Several leading projects including the integrated tourism complexes have their own qualified interior designers to take care of interior design aspects of the project.

SCIENTIFIC COLLEGE OF DESIGN

In the Scientific College of Design, Muscat an interior design programme is being offered to aspiring learners by a group of qualified professionals. Dr. Mona Kamal Ismail, head of interior design department pointed out that the college is the only one in the entire GCC region specializing in design and arts. The college which offers bachelor degree and diploma in interior and graphic design as well as fine arts programmes is affiliated to The Lebanese American University. The curricula are based on a liberal art model of education. The programme offers theory and history courses as well as technical courses and design studios.

Though the country does not have a professional organization of interior designers or set standards on interior design, these are likely to happen in the near future.

Students who graduated from the college are working in different institutions in the capital such as furniture stores, consultancy offices, and specialised design firms. Some of them plan to open offices in interiors of the Sultanate also, thereby spreading awareness of interior design even in far flung areas. Presently there are a group of qualified Omani men and women who graduated from the college

working as interior designers which will lead to local influences in interior design. Many companies are hiring students from the college as interior designers once they graduate.

FUNCTIONAL ASPECTS OF INTERIOR DESIGN

Speaking on the importance of interior design, Dr. Mona says interiors of a home or a commercial institution could be done in a way which would make people more comfortable and more efficient. Professional interior design can assist special groups like children, physically challenged individuals, or older adults to maintain their independence.

Familiar examples of commercial interior design to serve business purpose are evident at fast food restaurants which use warm colours and not so comfortable chairs which make people finish their food quickly. Several financial institutions organise space inside their office to help users with efficient circulation. They use diverse colours at different counters to differentiate services quickly. It makes people who arrive at the place identify the counter where the service which they need is provided.

Interiors of residential buildings in Oman maintain traditional space division such as separate Majlis for men and women. The exterior architecture of buildings in Muscat has a unique style due to the standards set by Muscat Municipality. The interior has to somewhat reflect the same style as the exterior. Interior design trends in Oman currently are influenced by the Asian and South East Asian trends. Omani culture is colourful which is influenced by Indian and Persian trends, noted Dr. Mona. Presently, the furniture used is mainly imported from Malaysia and China which has dark colours, she said.The awareness on eco friendly paint and fabrics which could be used is yet to catch up in the Sultanate. People still use paints to impart colour to walls and use of wall paper is not popular, Dr. Mona noted. For flooring, marble and porcelain tiles are the norm.

Interior design involves making any space into an effective setting for the range of human activities taking places there. It is essential to improve the quality of life in residential, commercial, and public settings. It is interesting to note the increasing development of such a field in Oman.

Muna Baquer, an expert interior designer noted that the idea of interior designing is yet to become popular in Oman. Here when one builds a home they visit neighbours’ homes and replicate ideas of interior design.

When you enter houses in Oman you don’t feel the differences, she said. Floorings are the same, ceilings are the same and colour scheme is also the same which is all white.

People take whatever available in the market. Sometimes they would approach painters and ask what is available.

There is significant French influence in the interior design of houses here. Window panes and columns are all French. Once you enter an Omani home there is separate majilis for men and women, corridor, another hall, staircase, three to four rooms scattered and a small family room. This is the normal trend, she said.

Interior designing in some of the big hotels in Oman is influenced by Omani traditions. The Barr Al Jissah Resort and Spa is an example of Omani traditions in interior design. However, increasing awareness on interior designing is also resulting in people giving importance to ensure functionality while designing specific areas of their home and offices.

MODERN SANITARY SOLUTIONS

Presently trend is catching up among the high end users including top hotels and offices to select sanitary ware, lighting solutions and furniture carefully so as to match each other and provide maximum comfort. Builders, interior designers and providers of electrical and sanitary solutions work in close coordination during the construction of many high end homes, hotels and offices.

Bathroom is one of the areas where a lot of planning and innovation is happening. Modern bathrooms have become a place to relax and refresh. As the awareness is becoming very high, those at the high end opt for designer sanitary wares, says a top end dealer of sanitary wares. Along with hassle free functioning people want exclusive sanitary wares for their homes.

Aesthetics have become an important concern of the high end users along with the functionality aspect. The market may see many innovations in interior designing of bathrooms in the coming days. Several leading companies are planning to introduce new products also in the segment this year. Awareness on ecology is also catching up slowly. Eco-friendly products are already available in the market.

Though the present trend indicates that majority prefer to paint their walls but this trend may also change in the coming days with the introduction of wall papers. An exclusive wall paper shop is coming up in the capital city. It is planning to introduce different varieties of wall papers in Oman market which are not available here. With people developing an interest for interior designing and more professional interior designers offering services in the market, it seems that the business of interior designing is all set to flourish in Oman in the coming days.

MURIYA TO HANDOVER APARTMENTS AT JEBEL SIFAH

AS MANY AS 156 APARTMENTS WILL BE READY FOR OCCUPATION BY THE END OF 2011. THE BOUTIQUE HOTEL AT THE PROJECT WOULD ALSO BE OPENED DURING THE PERIOD

Construction work at Jebel Sifah, the integrated tourism complex (ITC) being developed by Muriya Tourism Development, is progressing and Phase I customers will start receiving their villas and apartments in the first quarter of 2011.

Bahaa Kareem, marketing director of Muriya, who updated journalists on the progress of the project, recently said 156 apartments belonging to the phase I of the project will be ready for occupation by early 2011. “The economic slowdown did not affect the project. We have sold all apartments and 70 per cent of villas of the phase I,” he said. Around 75 per cent of properties are sold to Omanis, he added.

Work is progressing in different stages in all the 18 apartment blocks, while finishing work is nearing completion on five blocks. A mock-up apartment has been completed, with the interiors done, to give a realistic view on design and space. The 63 villas, part of the initial release will be designed in eight different styles of which 41 are nearing completion.

The Jebel Sifa complex has one, two and three bed-room apartments fitted with air conditioners, kitchen and home appliances. The prices start from 130,000 rials onwards.

OTHER PROJECTS

Work on phase I of Muriya projects at Al Sodah Island and Salalah are progressing, said Kareem. The first phase will feature five hotels including one boutique hotel. Nearing completion, the boutique hotel will open in the first quarter of 2011 and will be managed by Muriya Hotel Division. Other hotels will be operated by some of the most reputed and prestigious brands in the hospitality sector that include Four Seasons Hotels & Resorts, Banyan Tree Hotels & Resorts and Missoni Hotel. The remaining one will be operated by a famous French hotel company. All the hotels are expected to be open by 2013.

In partnership with the iconic fashion house of the same name, Hotel Missoni will be stylish, intimate, contemporary and eclectic in design. The property with 250 room keys will be designed by Michael Graves and Rosita Missoni will oversee the interiors. Construction for the Missoni Hotel is scheduled to start this year. Kareem said Muriya will shortly announce the release of new units and schemes. Selective hotel managed new apartments and villas will offer a unique rent back guarantee programme and will be operated by top brand hotels, a first of its kind associated with freehold properties in Oman. The new villas to be handed over will have new convenient sizes. An on-site sales office will be set up soon, to further enhance the service to the customers, including site visits. Muriya has also set up a ‘Home Design’ department, and are providing owners furniture packages, interior finishing, audio-visual packages, landscaping and upgrade options.

ACCESS TO THE PROJECT

The roads leading to Sifah will be widened for safe access to the destination. The internal roads within the project have already been laid out, providing clear access to the properties and the marina. Final revetment for internal roads will be finished by the beginning of next year.

Kareem said that there are plans to introduce a ferry service from Muscat to the project. It would provide easy and quick transportation to residents and visitors. The central hub of ‘Jebel Sifah’ is the marina that will be bustling with an array of activities surrounded by lively restaurants, cafes and apartment blocks with narrow, shaded, cobbled roads when completed. A lot of thought and attention has gone into the planning to ensure that the feel and look of the place remains open and uncluttered,at the same time aesthetically pleasing.

The marina was flooded in November 2009 and will be soon ready for berthing boats. High quality weather-resistant pontoons have been put in place that will provide space for up to 150 boats. A promenade will weave through the lively marina town that will also accommodate the marina boutique hotel having 55 rooms.

CORPORATE SOCIAL RESPONSIBILITY

On the welfare measures being carried out by Muriya as part of corporate social responsibilities, Kareem said a beach is being developed in the area which the general public could also avail of. A restaurant has been constructed at the beach which would be run by the local people under the supervision of Muriya, said Kareem.

Muriya was established in 2006 when Egypt’s Orascom Hotels and Development (with 70 per cent stake) and Omani government owned Omran (with 30 per cent stake) came together in a joint venture.

Structural requirements

1. Introduction

To perform its function of supporting a building in response to whatever loads may be applied to it, a structure must possess four properties: it must be capable of achieving a state of equilibrium, it must be stable, it must have adequate strength and it must have adequate rigidity. The meanings of these terms are explained in this chapter. The influence of structural requirements on the forms which are adopted for structures is also discussed. The treatment is presented in a non-mathematical way and the definitions which are given are not those of the theoretical physicist; they are simply statements which are sufficiently precise to allow the significance of the concepts to structural design to be appreciated.

2. Equilibrium

Structures must be capable of achieving a state of equilibrium under the action of applied load. This requires that the internal configuration of the structure together with the means by which it is connected to its foundations must be such that all applied loads are balanced exactly by reactions generated at its foundations. The wheelbarrow provides a simple demonstration of the principles involved. When the wheelbarrow is at rest it is in a state of static equilibrium. The gravitational forces generated by its self weight and that of its contents act vertically downwards and are exactly balanced by reacting forces acting at the wheel and other supports. When a horizontal force is applied to the wheel barrow by its operator it moves horizontally and is not therefore in a state of static equilibrium.This occurs because the interface between the wheelbarrow and the ground is incapable of generating horizontal reacting forces. The wheelbarrow is both a structure and a machine: it is a structure under the action of gravitational load and a machine under the action of horizontal load.

Despite the famous statement by one celebrated commentator, buildings are not machines1. Architectural structures must,therefore, be capable of achieving equilibrium under all directions of load.

3. Geometric stability

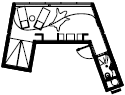

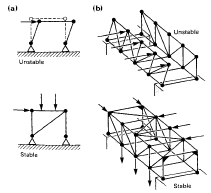

Geometric stability is the property which preserves the geometry of a structure and allows its elements to act together to resist load. The distinction between stability and equilibrium is illustrated by the framework shown in Fig. 2.1 which is capable of achieving a state of equilibrium under the action of gravitational load. The equilibrium is not stable, however, because the frame will collapse if disturbed laterally2.

Fig. 2.1 A rectangular frame with four hinges is capable

of achieving a state of equilibrium but is unstable because

any slight lateral disturbance to the columns will induce it

to collapse. The frame on the right here is stabilised by the

diagonal element which makes no direct contribution to

the resistance of the gravitational load.

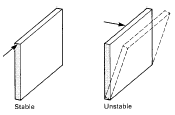

This simple arrangement demonstrates that the critical factor, so far as the stability of any system is concerned, is the effect on it of a small disturbance. In the context of structures this is shown very simply in Fig. 2.2 by the comparison of tensile and compressive elements. If the alignment of either of these is disturbed, the tensile element is pulled back into line following the removal of the disturbing agency but the compressive element, once its initially perfect alignment has been altered, progresses to an entirely new position. The fundamental issue of stability is demonstrated here, which is that stable systems revert to their original state following a slight disturbance whereas unstable systems progress to an entirely new state.

The parts of structures which tend to be unstable are the ones in which compressive forces act and these parts must therefore be given special attention when the geometric stability of an arrangement is being considered. The columns in a simple rectangular framework are examples of this(Fig. 2.1). The three-dimensional bridge structure of Fig. 2.3 illustrates another potentially unstable system. Compression occurs in the horizontal elements in the upperparts of this frame when the weight of an object crossing the bridge is carried. The arrangement would fail by instability when this load was applied due to inadequate restraint of these compression parts. The compressive internal forces, which would inevitably occur with some degree of eccentricity, would push the upper elements out of alignment and cause the whole structure to collapse.

because the loads pull it back into line following a disturbance.

The compressive element on the right is fundamentally unstable.

Fig. 2.3 The horizontal elements in the tops of the bridge girders

are subjected to compressive internal force when the load is applied.

The system is unstable and any eccentricity which is present initially

causes an instability-type failure to develop.

The geometric instability of the arrangements in Figures 2.1 and 2.3 would have been obvious if their response to horizontal load had been considered (Fig. 2.4).This demonstrates one of the fundamental requirements for the geometric stability of any arrangement of elements, which is that it must be capable of resisting loads from orthogonal directions (two orthogonal directions for plane arrangements and three for three-dimensional arrangements). This is another way of saying that an arrangement must be capable of achieving a state of equilibrium in response to forces from three orthogonal directions. The stability or otherwise of a proposed arrangement can therefore be judged by considering the effect on it of sets of mutually perpendicular trial forces: if the arrangement is capable of resisting all of these then it is stable, regardless of the loading pattern which will actually be applied to it in service. Conversely, if an arrangement is not capable of resisting load from three orthogonal directions then it will be unstable in service even though the load which it is designed to resist will be applied from only one direction.

(a) The two-dimensional system is stable if it is capable of achieving equilibrium in response to forces from two mutually perpendicular directions.

(b) The three-dimensional system is stable if it is capable of resisting forces from three directions. Note that in the case illustrated the resistance of transverse horizontal load is achieved by the insertion of rigid joints in the end bays.

It frequently occurs in architectural design that a geometry which is potentially unstable must be adopted in order that other architectural requirements can be satisfied. For example, one of the most convenient structural geometries for buildings, that of the rectangular frame, is unstable in its simples thing e-jointed form, as has already been shown.Stability can be achieved with this geometry by the use of rigid joints, by the insertion of a diagonal element or by the use of a rigid diaphragm which fills up the interior of the frame (Fig. 2.5). Each of these has disadvantages. Rigid joints are the most convenient from a space-planning point of view but are problematic structurally because they can render the structure statically indeterminate (see Appendix 3). Diagonal elements and diaphragms block the frame work and can complicate space planning. In multi-panel arrangements, however, it is possible to produce stability without blocking every panel.The row of frames in Fig. 2.6, for example, is stabilised by the insertion of a single diagonal.

Fig. 2.5 A rectangular frame can be stabilised

by the insertion of (a) a diagonal element or (b) a rigid

diaphragm, or (c) by the provision of rigid joints.

A single rigid joint is in fact sufficient to provide stability.

Fig. 2.6 A row of rectangular frames is stable if one panel

only is braced by any of the three methods shown in Fig. 2.5.

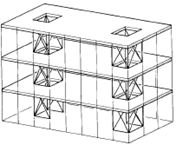

Where frames are parallel to each other the three-dimensional arrangement is stable if a few panels in each of the two principal directions are stabilised in the vertical plane and the remaining frames are connected to these by diagonal elements or diaphragms in the horizontal plane (Fig. 2.7). A three-dimensional frame can therefore be stabilised by the use of diagonal elements or diaphragms in a limited number of panels in the vertical and horizontal planes. In multi-storey arrangements these systems must be provided at every storey level.

Fig. 2.7 These frames containt he minimum

number of braced panels required for stability.

None of the components which are added to stabilise the geometry of the rectangular frame in Fig. 2.7 makes a direct contribution to the resistance of gravitational load (i.e. the carrying of weight, either of the structure itself or of the elements and objects which it supports). Such elements are called bracing elements. Arrangements which do not require bracing elements, either because they are fundamentally stable or because stability is provided by rigid joints, are said to be self-bracing.

Most structures contain bracing elements whose presence frequently affects both the initial planning and the final appearance of the building which it supports. The issue of stability, and in particular the design of bracing systems, is therefore something which affects the architecture of buildings.

Where a structure is subjected to loads from different directions, the elements which are used solely for bracing when the principal load is applied frequently play a direct role in resisting secondary load. The diagonal elements in the frame of Fig. 2.7, for example,would be directly involved in the resistance of any horizontal load which was applied, such as might occur due to the action of wind. Because real structures are usually subjected to loads from different directions, it is very rare for elements to be used solely for bracing.

The nature of the internal force in bracing components depends on the direction in which the instability which they prevent occurs. In Fig. 2.8, for example, the diagonal element will be placed in tension if the frame sways to the right and in compression if it sways to the left. Because the direction of sway due to instability cannot be predicted when the structure is being designed, the single bracing element would have to be made strong enough to carry either tension or compression. The resistance of compression requires a much larger size of cross-section than that of tension, however,especially if the element is long3, and this is a critical factor in determining its size. It is normally more economical to insert both diagonal elements into a rectangular frame (cross-bracing) than a single element and to design both of them as tension-only elements.When the panel sways due to instability the element which is placed in compression simply buckles slightly and the whole of the restraint is provided by the tension diagonal.

caused by instability is always resisted by a diagonal

element acting in tension. The compressive diagonal

buckles slightly and carries no load.

It is common practice to provide more bracing elements than the minimum number required so as to improve the resistance of three-dimensional frameworks to horizontal load. The framework in Fig. 2.7, for example,although theoretically stable, would suffer considerable distortion in response to a horizontal load applied parallel to the long side of the frame at the opposite end from the vertical-plane bracing. A load applied parallel to the long side at this end of the frame would also cause a certain amount of distress as some movement of joints would inevitably occur in the transmission of it to the vertical-plane bracing at the other end. In practice the performance of the frame is more satisfactory if vertical-plane bracing is provided at both ends (Fig. 2.9). This gives more restraint than is necessary for stability and makes the structure statically in determinate (see Appendix 3), but results in the horizontal loads being resisted close to the points where they are applied to the structure.Another practical consideration in relation to the bracing of three-dimensional rectangular frames is the length of the diagonal elements which are provided. These sag in response to their own weight and it is therefore advantageous to make them as short as possible. For this reason bracing elements are frequently restricted to a part of the panel in which they are located. The frame shown in Fig. 2.10 contains this refinement.

Fig. 2.9 In practical bracing schemes more elements

than are strictly necessary to ensure stability are provided

to improve the performance of frameworks in resisting

horizontal load. Frame (a) is stable but will suffer distortion

in response to horizontal load on the side walls.Its performance

is enhanced if a diagonal element is provided in both end walls

(b). The lowest framework (c)contains the minimum number of elements

required to resist effectively horizontal load from the two principal horizontal

directions. Note that the vertical-plane bracing elements are

distributed around the structure in asymmetrical configuration.

Fig. 2.10 In practice, bracing elements are

frequently confined to a part of each panel only.

Figures 2.11 and 2.12 show typical bracing systems for multi-storey frameworks. Another common arrangement, in which floor slabs act as diaphragm-type bracing in the horizontal plane in conjunction with vertical-plane bracing of the diagonal type, is shown in Fig.2.13. When the rigid-joint method is used it is normal practice to stabilise all panels individually by making all joints rigid. This eliminates the need for horizontal-plane bracing altogether, although the floors normally act to distribute through the structure any unevenness in the application of horizontal load. The rigid-joint method is the normal method which is adopted for reinforced concrete frames, in which continuity through junctions between elements can easily be achieved; diaphragm bracing is also used, however, in both vertical and horizontal planes in certain types of reinforced concrete frame.

Load bearing wall structures are those in which the external walls and internal partitions serve as vertical structural elements. They are normally constructed of masonry, reinforced concrete or timber, but combinations of these materials are also used. In all cases the joints between walls and floors are normally incapable of resisting bending action (in other words they behave as hinges) and the resulting lack of continuity means that rigid-frame action cannot develop. Diaphragm bracing,provided by the walls themselves, is used to stabilise these structures. concrete or timber, but combinations of these materials are also used. In all cases the joints between walls and floors are normally incapable of resisting bending action (in other words they behave as hinges) and the resulting lack of continuity means that rigid-frame action cannot develop. Diaphragm bracing,provided by the walls themselves, is used to stabilise these structures.

Fig. 2.11 A typical bracing scheme for a multi-storey

framework. Vertical-plane bracing is provided in a limited

number of bays and positioned symmetrically on plan.

All other bays are linked to this by diagonal bracing in

the horizontal plane at every storey level.

Fig. 2.12 These drawings of floor grid patterns for steel

frameworks show typical locations for vertical-plane bracing.

Fig. 2.13 Concrete floor slabs are normally used

as horizontal-plane bracing of the diaphragm type which

acts in conjunction with diagonal bracing in the vertical planes.

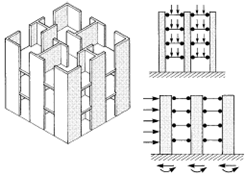

A wall panel has high rotational stability in its own plane but is unstable in the out-of-plane direction (Fig. 2.14); vertical panels must, therefore, be grouped in pairs at right angles to each other so that they provide mutual support. For this to be effective the structural connection which is provided in the vertical joint between panels must be capable of resisting shear4. Because load bearing wall structures are normally used for multi-cellular buildings, the provision of an adequate number of vertical-plane bracing diaphragms in two orthogonal directions is normally straight forward (Fig. 2.15). It is unusual therefore for bracing requirements to have a significant effect on the internal planning of this type of building.

Fig. 2.14 Walls are unstable in the out-of-plane direction and

must be grouped into orthogonal arrangements for stability.

Fig. 2.15 Load bearing masonry buildings are normally

multi-cellular structures which contain walls running in

two orthogonal directions. The arrangement is inherently stable.

The need to ensure that a structural framework is adequately braced is a factor that can affect the internal planning of buildings.The basic requirement is that some form of bracing must be provided in three orthogonal planes. If diagonal or diaphragm bracing is used in the vertical planes this must be accommodated within the plan. Because vertical-plane bracing is most effective when it is arranged symmetrically, either in internal cores or around the perimeter of the building,this can affect the space planning especially in tall buildings where the effects of wind loading are significant.

4. Strength and rigidity

4.1 Introduction

The application of load to a structure generates internal forces in the elements and external reacting forces at the foundations (Fig.2.16) and the elements and foundations must have sufficient strength and rigidity to resist these. They must not rupture when the peak load is applied; neither must the deflection which results from the peak load be excessive.

Fig. 2.16 The structural elements of a building conduct

the loads to the foundations. They are subjected to internal

forces that generate stresses the magnitudes of which depend

on the intensities of the internal forces and the sizes of the elements.

The structure will collapse if the stress levels exceed the strength of the material.

The requirement for adequate strength is satisfied by ensuring that the levels of stress which occur in the various elements of a structure, when the peak loads are applied, are within acceptable limits. This is chiefly a matter of providing elements with cross-sections of adequate size, given the strength of the constituent material. The determination of the sizes required is carried out by structural calculations. The provision of adequate rigidity is similarly dealt with.

Structural calculations allow the strength and rigidity of structures to be controlled precisely. They are preceded by an assessment of the load which a structure will be required to carry. The calculations can be considered to be divisible into two parts and to consist firstly of the structural analysis, which is the evaluation of the internal forces which occur in the elements of the structure, and secondly,the element-sizing calculations which are carried out to ensure that they will have sufficient strength and rigidity to resist the internal forces which the loads will cause. In many cases, and always for statically indeterminate structures (see Appendix 3), the two sets of calculations are carried out together, but it is possible to think of them as separate operations and they are described separately here.

4.2 The assessment of load

The assessment of the loads which will act on a structure involves the prediction of all the different circumstances which will cause load to be applied to a building in its lifetime (Fig.2.17) and the estimation of the greatest magnitudes of these loads. The maximum load could occur when the building was full of people, when particularly heavy items of equipment were installed, when it was exposed to the force of exceptionally high winds or as a result of many other eventualities. The designer must anticipate all of these possibilities and also investigate all likely combinations of them.

The evaluation of load is a complex process,but guidance is normally available to the designer of a structure from loadingstandards5. These are documents in which data and wisdom gained from experience are presented systematically in a form which allows the information to be applied in design.

Fig. 2.17 The prediction of the maximum load which will occur is one of the most problematic aspects of structural calculations. Loading standards are provided to assist with this but assessment of load is nevertheless one of the most imprecise parts of the structural calculation process.

4.3 The analysis calculations

The purpose of structural analysis is to determine the magnitudes of all of the forces,internal and external, which occur on and in a structure when the most unfavourable load conditions occur. To understand the various processes of structural analysis it is necessary to have a knowledge of the constituents of structural force systems and an appreciation of concepts, such as equilibrium, which are used to derive relationships between them. These topics are discussed in Appendix 1.

In the analysis of a structure the external reactions which act at the foundations and the internal forces in the elements are calculated from the loads. This is a process in which the structure is reduced to its most basic abstract form and considered separately from the rest of the building which it will support.

An indication of the sequence of operations which are carried out in the analysis of a simple structure is given in Fig. 2.18. After a preliminary analysis has been carried out to evaluate the external reactions, the structure is subdivided into its main elements by making ‘imaginary cuts’ (see Appendix 1.7) through the junctions between them. This creates a set of‘free-body-diagrams’ (Appendix 1.6) in which the forces that act between the elements are exposed. Following the evaluation of these inter-element forces the individual elements are analysed separately for their internal forces by further applications of the ‘imaginary cut ’technique. In this way all of the internal forces in the structure are determined.

Fig. 2.18 In structural analysis the complete structure is broken down into two-dimensional components and the internal forces in these are subsequently calculated. The diagram shows the pattern forces which result from gravitational load on the roof of a small building. Similar breakdowns are carried out for the other forms of load and a complete picture is built up of the internal forces which will occur in each element during the life of the structure.

In large, complex, statically in determinate structures the magnitudes of the internal forces are affected by the sizes and shapes of the element cross-sections and the properties of the constituent materials, as well as by the magnitudes of the loads and the overall geometry of the structure. The reason for this is explained in Appendix 3. In these circumstances the analysis and element-sizing calculations are carried out together in a trial and error process which is only feasible in the context of computer-aided design.The different types of internal force which can occur in a structural element are shown in Fig. 2.19. As these have a very significant influence on the sizes and shapes which are specified for elements they will be described briefly here.In Fig. 2.19 an element is cut through at a particular cross-section. In Fig. 2.19 (a) the forces which are external to one of the resulting sub-elements are marked. If these were indeed the only forces which acted on the sub-element it would not be in a state of equilibrium. For equilibrium the forces must balance and this is clearly not the case here;an additional vertical force is required for equilibrium. As no other external forces are present on this part of the element the extra force must act on the cross-section where the cut occurred. Although this force is external to the sub-element it is an internal force so far as the complete element is concerned and is called the ‘shear force’. Its magnitude at the cross-section where the cut was made is simply the difference between the external forces which occur to one side of the cross-section, i.e. to the left of the cut.

Fig. 2.19 The investigation of internal forces in a simple

beam using the device of the ‘imaginary cut’. The cut

produces a free-body-diagram from which the nature of the

internal forces at a single cross-section can be deduced.

The internal forces at other cross-sections can be

determined from similar diagrams produced by cuts made

in appropriate places. (a) Not in equilibrium. (b) Positional

equilibrium but not in rotational equilibrium. (c)

Positional and rotational equilibrium. The shear force on

the cross-section 1.5 m from the left-hand support is

15 kN; the bending moment on this cross-section is

22.5 kNm.

Once the shear force is added to the diagram the question of the equilibrium of the sub-element can once more be examined. In fact it is still not in a state of equilibrium because the set of forces now acting will produce a turning effect on the sub-element which will cause it to rotate in a clockwise sense. For equilibrium an anti-clockwise moment is required and as before this must act on the cross-section at the cut because no other external forces are present.The moment which acts at the cut and which is required to establish rotational equilibrium is called the bending moment at the cross-section of the cut. Its magnitude is obtained from the moment equation of equilibrium for the free-body-diagram. Once this is added to the diagram the system is in a state of static equilibrium, because all the conditions for equilibrium are now satisfied(see Appendix 1).

Shear force and bending moment are forces which occur inside structural elements and they can be defined as follows. The shear force at any location is the amount by which the external forces acting on the element, to one side of that location, do not balance when they are resolved perpendicular to the axis of the element. The bending moment at a location in an element is the amount by which the moments of the external forces acting to one side of the location, about any point in their plane, do not balance. Shear force and bending moment occur in structural elements which are bent by the action of the applied load. Beams and slabs are examples of such elements.

Fig. 2.20 The ‘imaginary cut’ is a device for exposing

internal forces and rendering them susceptible to

equilibrium analysis. In the simple beam shown here shear

force and bending moment are the only internal forces

required to produce equilibrium in the element isolated by

the cut. These are therefore the only internal forces which

act on the cross-section at which the cut was made. In the

case of the portal frame, axial thrust is also required at the

cross-section exposed by the cut.

One other type of internal force can act on the cross-section of an element, namely axial thrust (Fig. 2.20). This is defined as the amount by which the external forces acting on the element to one side of a particular location do not balance when they are resolved parallel to the direction of the element. Axial thrust can be either tensile or compressive.

In the general case each cross-section of a structural element is acted upon by all three internal forces, namely shear force, bending moment and axial thrust. In the element-sizing part of the calculations, cross-section sizes are determined that ensure the levels of stress which these produce are not excessive. The efficiency with which these internal forces can be resisted depends on the shape of the cross-section.

The magnitudes of the internal forces in structural elements are rarely constant along their lengths, but the internal forces at any cross-section can always be found by making an ‘imaginary cut’ at that point and solving the free-body-diagram which this creates.Repeated applications of the ‘imaginary cut ’technique at different cross-sections (Fig.2.21), allows the full pattern of internal forces to be evaluated. In present-day practice these calculations are processed by computer and the results presented graphically in the form of bending moment, shear force and axial thrust diagrams for each structural element.

Fig. 2.21 The magnitudes of internal forces normally vary

along the length of a structural element. Repeated use of

the ‘imaginary cut’ technique yields the pattern of internal

forces in this simple beam.

The shapes of bending moment, shear force and axial thrust diagrams are of great significance for the eventual shapes of structural elements because they indicate the locations of the parts where greatest strength will be required. Bending moment is normally large in the vicinity of mid-span and near rigid joints. Shear force is highest near support joints. Axial thrust is usually constant along the length of structural elements.

4.4 Element-sizing calculations

The size of cross-section which is provided for a structural element must be such as to give it adequate strength and adequate rigidity. In other words, the size of the cross-section must allow the internal forces determined in the analysis to be carried without overloading the structural material and without the occurrence of excessive deflection. The calculations which are carried out to achieve this involve the use of the concepts of stress and strain. In the sizing calculations each element is considered individually and the area of cross-section determined which will maintain the stress at an acceptable level in response to the peak internal forces. The detailed aspects of the calculations depend on the type of internal force and, therefore, the stress involved and on the properties of the structural material.As with most types of design the evolution of the final form and dimensions of a structure is, to some extent, a cyclic process. If the element-sizing procedures yield cross-sections which are considered to be excessively large or unsuitable in some other way, modification of the overall form of the structure will be under taken so as to redistribute the internal forces. Then, the whole cycle of analysis and element-sizing calculations must be repeated.If a structure has a geometry which is stable and the cross-sections of the elements are sufficiently large to ensure that it has adequate strength it will not collapse under the action of the loads which are applied to it. It will therefore be safe, but this does not necessarily mean that its performance will be satisfactory (Fig. 2.22). It may suffer a large amount of deflection under the action of the load and any deformation which is large enough to cause damage to brittle building components, such as glass windows, or to cause alarm to the building’s occupants or even simply to cause unsightly distortion of the building’s form is a type of structural failure.

collapse, but excessive flexibility can render it unfit for its

purpose.

The deflection which occurs in response to a given application of load to a structure depends on the sizes of the cross-sections of the elements6and can be calculated once element dimensions have been determined. If the sizes which have been specified to provide adequate strength will result in excessive deflection they are increased by a suitable amount. Where this occurs it is the rigidity requirement which is critical and which determines the sizes of the structural elements. Rigidity is therefore a phenomenon which is not directly related to strength; it is a separate issue and is considered separately in the design of structures.

5. Conclusion

In this chapter the factors which affect the basic requirements of structures have been reviewed.The achievement of stable equilibrium has been shown to be dependent largely on the geometric configuration of the structure and is therefore a consideration which affects the determination of its form. A stable form can almost always be made adequately strong and rigid, but the form chosen does affect the efficiency with which this can be accomplished.So far as the provision of adequate strength is concerned the task of the structural designer is straightforward, at least in principle. He or she must determine by analysis of the structure the types and magnitudes of the internal forces which will occur in all of the elements when the maximum load is applied. Cross-section shapes and sizes must then be selected such that the stress levels are maintained within acceptable limits. Once the cross-sections have been determined in this way the structure will be adequately strong. The amount of deflection which will occur under the maximum load can then be calculated. If this is excessive the element sizes are increased to bring the deflection within acceptable limits. The detailed procedures which are adopted for element sizing depend on the types of internal force which occur in each part of the structure and on the properties of the structural material.