Structural Materials - Timber

|

|

Timber has been used as a structural material from earliest times. It possesses both tensile and compressive strength and, in the structural role is therefore suitable for elements which carry axial compression, axial tension and bending-type loads. Its most widespread application in architecture has been in buildings of domestic scale in which it has been used to make complete structural frameworks, and for the floors and roofs in load bearing masonry structures. Rafters, floor beams, skeleton frames, trusses, built-up beams of various kinds, arches, shells and folded forms have all been constructed in timber (Pic. 1, 2, 3 and 4).

The fact of timber having been a living organism is responsible for the nature of its physical properties. The parts of the tree which are used for structural timber – the heartwood and sapwood of the trunk – have a structural function in the living tree and therefore have,in common with most organisms, very good structural properties. The material is composed of long fibrous cells aligned parallel to the original tree trunk and therefore to the grain which results from the annual rings. The material of the cell walls gives timber its strength and the fact that its constituent elements are of low atomic weight is responsible for its low density. The lightness in weight of timber is also due to its cellular internal structure which produces element cross-sections which are permanently‘improved’.

Parallel to the grain, the strength is approximately equal in tension and compression so that planks aligned with the grain can be used for elements which carry axial compression, axial tension or bending-type loads as noted above. Perpendicular to the grain it is much less strong because the fibres are easily crushed or pulled apart when subjected to compression or tension in this direction.

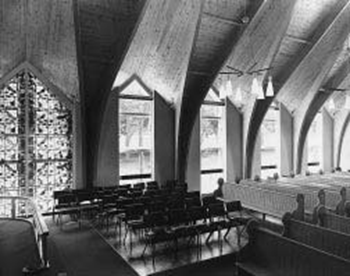

A series of laminated timber portalframes is used here to provide

a vault-like interior. Timber is also used for secondary

structural elements and interior lining

This weakness perpendicular to the grain causes timber to have low shear strength when subjected to bending-type loads and also makes it intolerant of the stress concentrations such as occur in the vicinity of mechanical fasteners such as bolts and screws. This can be mitigated by the use of timber connectors,which are devices designed to increase the area of contact through which load is transmitted in a joint. Many different designs of timber connector are currently available (Pic. 2.) but, despite their development, the difficulty of making satisfactory structural connections with mechanical fasteners is a factor which limits the load carrying capacity of timber elements, especially tensile elements.

The development in the twentieth century of structural glues for timber has to some extent solved the problem of stress concentration at joints, but timber which is to be glued must be very carefully prepared if the joint is to develop its full potential strength and the curing of the glue must be carried out under controlled conditions of temperature and relative humidity. This is impractical on building sites and has to be regarded as a pre-fabricating technique.

in bolted connections. A selection of different types is shown here

Timber suffers from a phenomenon known as ‘moisture movement’. This arises because the precise dimensions of any piece of timber are dependent on its moisture content (the ratio of the weight of water which it contains to its dry weight, expressed as a percentage). This is affected by the relative humidity of the environment and as the latter is subject to continuous change, the moisture content and therefore the dimensions of timber also fluctuate continuously. Timber shrinks following a reduction in moisture content due to decreasing relative humidity and swells if the moisture content increases. So far as the structural use of timber is concerned, one of the most serious consequences of this is that joints made with mechanical fasteners tend to work loose.

The greatest change to the moisture content of a specimen of timber occurs following the felling of a tree after which it undergoes a reduction from a value of around 150 percent in the living tree to between 10 and 20 percent, which is the normal range for moisture content of timber in a structure. This initial drying out causes a large amount of shrinkage and must be carried out in controlled conditions if damage to the timber is to be avoided. The controlled drying out of timber is known as seasoning. It is a process in which the timber must be physically restrained to prevent the introduction of permanent twists and other distortions caused by the differential shrinkage which inevitably occurs, on a temporary basis, due to unevenness in the drying out. The amount of differential shrinkage must be kept to a minimum and this favours the cutting of the timber into planks with small cross-sections, because the greatest variation in moisture content occurs between timber at the core of a plank and that at the surface where evaporation of moisture takes place.

Timber elements can be either of sawn timber, which is simply timber cut directly from a tree with little further processing other than shaping and smoothing, or manufactured products, to which further processing has been applied. Important examples of the latter are laminated timber and plywood.

The forms in which sawn timber is available are, to a large extent, a consequence of the arboreal origins of the material. It is convenient to cut planks from tree trunks by sawing parallel to the trunk direction and this produces straight, parallel-sided elements with rectangular cross-sections. Basic sawn-timber components are relatively small (maximum length around 6m and maximum cross-section around 75mm x 250mm) due partly to the obvious fact that the maximum sizes of cross-section and length are governed by the size of the original tree, but also to the desirability of having small cross-sections for the seasoning process. They can be combined to form larger,composite elements such as trusses with nailed, screwed or bolted connections. The scale of structural assemblies is usually modest, however, due to both the small sizes of the constituent planks and to the difficulty (already discussed) of making good structural connections with mechanical fasteners.

Timber is used in load bearing – wall structures both as the horizontal elements in masonry buildings and in all-timber configurations in which vertical timber elements are spaced close together to form wall panels (Pic. 3). The use of timber in skeleton frame structures (beams and columns as opposed to closely spaced joists and wall panels) is less common because the concentration of internal forces which occurs in these normally requires that a stronger material such as steel be adopted. In all cases spans are relatively small, typically 5m for floor structures of closely spaced joists of rectangular cross-section, and 20m for roof structures with triangulated elements. All-timber structures rarely have more than two or three storeys.

form of construction in which all of the structural elements

in the walls, floors and roof are of timber. An internal wall of closely

spaced sawn-timber elements is here shown supporting

the upper floor of a two-storey building. Note temporary

bracing which is necessary for stability until cross-walls are inserted

Timber products are manufactured by gluing small timber elements together in conditions of close quality control. They are intended to exploit the advantages of timber while at the same time minimising the effects of its principal disadvantages, which are variability,dimensional instability, restrictions in the sizes of individual components and anisotropic behaviour. Examples of timber products are laminated timber, composite boards such as plywood, and combinations of sawn timber and composite board (Pic. 4).

Laminated timber (Pic. 4c) is a product in which elements with large rectangular cross-sections are built up by gluing together smaller solid timber elements of rectangular cross-section. The obvious advantage of the process is that it allows the manufacture of solid elements with much larger cross-sections than are possible in sawn timber. Very long elements are also possible because the constituent boards are jointed end-to-end by means of finger joints (Pic. 5). The laminating process also allows the construction of elements which are tapered or have curved profiles. Arches (Pics 6 and 7) and portal frame elements (Pic. 1) are examples of this.

Pic. 4. The I-beam with the plywood web

(b) and the laminated beam

(c) are examples of manufactured timber products.

These normally have better technical properties

than plain sawn timber elements such as that shown in

(a). The high levels of glue impregnation in

manufactured beams reduce dimensional

instability, and major defects, such as knots,

are removed from constituent sub elements.

Pic. 5. ‘Finger’ joints allow the constituent boards of laminated

timber elements to be produced in long lengths.

They also make possible the cutting out of defects such as knots

Pic. 6. Sports Dome, Perth, Scotland, UK. Laminated timber built-up

sections can be produced in a variety of configurations in addition to straight beams.

Here a series of arch elements is used to produce the framework of a dome.

The general quality and strength of laminated timber is higher than that of sawn timber for two principal reasons. Firstly, the use of basic components which have small cross-sections allows more effective seasoning,with fewer seasoning defects than can be achieved with large sawn-timber elements.Secondly, the use of the finger joint, which causes a minimal reduction in strength in the constituent boards, allows any major defects which are present in these to be cut out. The principal use of laminated timber is as an extension to the range of sawn-timber elements and it is employed in similar structural configurations – for example as closely spaced joists – and allows larger spans to be achieved. The higher strength of laminated timber elements also allows it to be used effectively in skeleton frame construction.

Composite boards are manufactured products composed of wood and glue. There are various types of these including plywood, block board and particle board, all of which are available in the form of thin sheets. The level of glue impregnation is high and this imparts good dimensional stability and reduces the extent to which anisotropic behaviour occurs.Most composite boards also have high resistance to splitting at areas of stress concentration around nails and screws.

Composite boards are used as secondary components such as gusset plates in built-up timber structures. Another common use is as the web elements in composite beams of I- or rectangular-box section in which the flanges are sawn timber (Pics 7 and 8).

elements are laminated timber arches which span 35 m.

Pic. 8. Built-up-beams with I-shaped cross-sections

consisting of sawn timber flanges connected by a

plywood web. The latter is corrugated which allows the

necessary compressive stability to be achieved with a

very thin cross-section

Pic. 9. Sports Stadium at Lähderanta, Sweden. The

primary structural elements are plywood timber arches

with rectangular box cross-sections

To sum up, timber is a material which offers the designers of buildings a combination of properties that allow the creation of lightweight structures which are simple to construct. However, its relatively low strength,the small sizes of the basic components and the difficulties associated with achieving good structural joints tend to limit the size of structure which is possible, and the majority of timber structures are small in scale with short spans and a small number of storeys. Currently, its most common application in architecture is in domestic building where it is used as a primary structural material either to form the entire structure of a building, as in timber wall-panel construction, or as the horizontal elements in load bearing masonry structures.

wow what an opportunity working for such a great brand!! you really did well landing that one. congrats! Solid Timber Floors Melbourne