Architectural Design In Steel # Frame design

|

|

1. The frame as the basic unit of construction

A framework is a three-dimensional assembly of steel members that form a self-supporting structure or enclosure. The most common and economic way to enclose a space is to use a series of two-dimensional frames that are spaced at equal intervals along one axis of the building, as shown in Figure 1(a). Stability is achieved in the two directions by the use of rigid framing, diagonal bracing, or through the supporting action of concrete shear walls or cores. This method of ‘extruding’ a building volume is equally applicable to any frame geometry, whether of single or multiple bays.

Three-dimensional frames can vary enormously in overall form,in the overall geometry of the individual members comprising them,and in the elements comprising the horizontal and vertical members.In these more complex frames, elements may be repeated, but the structure relies for its effectiveness on mutual support in three dimensions (see Figure 1(b)).

Multi-storey building frames comprise beams and columns,generally in an orthogonal arrangement. The grillage of members in the floor structure generally comprise secondary beams that support the floor slab and primary beams that support the secondary beams.The primary beams tend to be heavier and often deeper than the secondary beams. Various structural alternatives for these members are presented in Chapter 4.

1. Examples of various forms of two-and three-dimensional frames to for men closures:

(a) two-dimensional frames(repeated to form a three-dimensional structure); and

(b) three-dimensional frames (repeated parts relying on mutual support)

2. Exposing the Frame

The exposure of the frame, either in part or in whole, obviously depends upon the relationship between the skeleton and external skin. The frame can be located completely external to the cladding,in which case it is given expression in the external appearance of the building. Alternatively, the frame can be located wholly internal to the cladding, in which case it may find little or no expression externally. Between these two extremes, the interaction of the frame and cladding establishes a further range of relationships. Buildings of an entirely different character emerge depending on these spatial relationships.

A simple example of a portal-frame structure that is continued outside the building envelope to visual effect is shown in Figure 2 In this case, the perforated cellular beams enhance the lightness of the structure whilst preserving its primary function as a rigid frame.

Basic building physics requirements, in terms of thermal insulation and control of condensation, also have to be addressed, particularly when the frame penetrates the building fabric.

2. Portal-frame structure created using cellular beams

2.1 Repetition of Frames

An exposed structure establishes a dominant rhythm in the elevational composition. More often than not, it is a simple and singular rhythm derived from the equal spacing of the primary frames. Various examples of repeated frames to form larger enclosures with increasing complexity are shown in Figure 3.

An external framework or skeleton often demands greater attention to detail, but conversely permits greater freedom in choice of structure form, as the structure is no longer dependent on the spatial confines of the internal envelope. Therefore, tension structures find their true expression in external structures.

3. Various illustrations of identical frames repeated at intervals

2.2 External frames

By selectively exposing or concealing structural members, emphasis can be given either to the primary frames, or to the wall and ceiling planes which define the building volume. In one of the early examples, Mies van der Rohe's Crown Hall building (see Figure 4),the large-span portal frame is clearly expressed, yet subtly woven into the fabric of the external wall. In other structures, a clearer distinctionis made between the external frame and building enclosure, such as by use of masts and cables in tension structures.

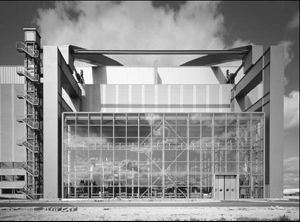

The Lufthansa terminal at Hamburg Airport uses a portal frame comprising plated box-sections to create a massive external skeleton (Figure 5).

3. Braced versus Rigid Frames

The fundamental structural requirement governing the design of connections in building frames is related to the strength and stiffness of the connections between the members, or of members to the foundations.

5. Lufthansa Terminal, Hamburg Airport (architect: VonGerkan Marg & Partners)

The connections may be one of three configurations defining these degrees of strength (or more correctly ‘resistance’) and stiffness :

(a) examples of effectively ‘rigid’ connections; and

(b) examples of effectively ‘pinned’ connections

1. Rigid (also called fixed or moment-resisting) connections(Figure 6 (a)).

2. Pinned (also called simple) connections (Figure 6 (b)).

3. Semi-rigid (also termed partial strength) connections.

Rigid frames require rigid connections in order to provide forstability at least in one direction. Braced frames are stabilised by vertically oriented bracing, and require only pinned connections.Rigid frames are often termed ‘sway frames’, because they are more flexible under horizontal loads than braced frames.

In a ‘rigid’ connection there is complete structural continuity between any two adjacent members. Moment (or rigid) connections are used in frames where there is a desire to omit vertical bracing in one or both directions. The main advantage of rigid frames is that an open space between columns can be created, which offers flexibility in choice of cladding, etc. (e.g. in glazed façades). However, the achievement of full continuity between members at the connection requires an extensive amount of fabrication and, as a consequence, this system is relatively expensive.

To achieve a nominally ‘pinned’ joint, the connections are made so as to permit the transfer of axial and shear forces, but not bending moments. Nominally simple connections may provide some small degree of rigidity, but this is ignored in structural design and these connections are treated as pinned. Examples of pinned connections are cleated, thin or partial depth end-plates, and fin-plate connections as illustrated in Figure 6(b).

Pinned connections are usually simple to fabricate and erect, and are the least expensive type of connection to produce. As a consequence, lateral stiffness must be introduced into the frame by other means.

Semi-rigid (and also partial strength) connections achieve some continuity through the connections, but are not classified as full strength, as they do not achieve the bending resistance of the connected members. These forms of connections are illustrated later on in Figure 5. They are used for low-rise frames in which horizontal forces are not so high, or in beams where some end fixity is beneficial to the control of deflections.

4. Portal-Frame Structures

Portal-frame type structures are examples of rigid frames that can take a number of forms. They were first developed in the 1960s, and have now become the most common form of enclosure for spans of 20 to 60 m. Portal frames are generally fabricated from hot-rolled sections, although they may be formed from lattice or fabricated girders. They are braced conventionally in the orthogonal direction.

In general, portal-frame structures are used in single-storey industrial type buildings where the main requirement is to achieve a large open area at ground level and, as such, these structures may not be of architectural significance. However, the basic principles can be used in a number of more interesting architectural applications, as illustrated in Figures 2 and 7. Also, portal frames can be used in other applications, such as in roof structures for multi-storey buildings, long-span exhibition halls, and atrium structures.

The frame members normally comprise rafters and columns with rigid connections between them. Tapered haunches are introduced to strengthen the rafters at the eaves and to form moment-resisting connections. Either pinned or fixed bases may be used. Roof and wall bracing is essential for the overall stability of the structure, especially during erection. Typical examples of portal-frame structures using hot-rolled sections, fabricated sections and lattice trusses are illustrated in Figure 8. Portal frames generally provide little opportunity for expression but, with care, the chosen details can enlighten the appearance of these relatively commonplace structures.

of a building for Modern Art Glass (architect:Foster and Partners)

Other applications of portalised structures are illustrated in Figures 9 and 10. The articulated lattice structure using tubular elements was used to great effect in the Sainsbury Centre, Norwich.An arch or mansard shape can be created from linear members, as in Figure 11.

In tied portals, the horizontal forces on the columns may be restrained by a tie at, or close to, the top of the column. Ties are usually not preferred because they can interfere with the headroom of the space. Long ties also require intermediate suspension support to prevent sag. However, ties can be detailed effectively, as illustrated in Clatter bridge Hospital in Figure 12.

10. Arched portal using tubular sections

11. Long-span portal frame used to create an arch structure

12. Tied portal frame used at Clatter bridge Hospital (architect: Austin-Smith: Lord)

5. Expressing the Connections

Connections exert a strong influence on the architectural form.Pinned and rigid connections are quite distinct and produce quite different forms and details. The discontinuity of a pinned connection can either be accentuated and given a clear expression in the structural form, or, alternatively, it can be made less apparent. By drawing such distinctions in relation to the individual frame, and then to the whole building form, offers the basis for expression.Rigid connections demand continuity between members and invite a different approach. They are required to transfer high moments and can appear heavy and complex. However, a rigid connection may also be achieved through parts that are pin-jointed,as simplified in Figure 13, and by example in the Sainsbury Centre in Figure 1. In these cases, moments are transferred by tension and compression in the connections.

Centre Pompidou, Paris (architect : Renzo Piano and Richard Rogers)

The end wall of the Centre Pompidou in Paris, shown in Figure3.14, illustrates an unusual application of the principle, where the typical pinned connection between the truss and column is elegantly transformed to a moment-resisting connection by the addition of a continuous tie from the ‘gerberette’ extension to the truss and attached to the foundations.

Depending upon the exact nature and locations of connections in a frame, the ‘reading’ of the individual members and the frame as a whole can vary markedly. This is further illustrated in Figure 15 for a three-bay frame, in which different formal relationships between members and individual bays are established by simply varying the locations of the pinned connections in the structure. All cases are structurally admissible, but can create entirely different details.

15. Different overall forms of the frame by varying type

and location of pinned connections

A good example of articulation within a structure is illustrated in Figure 16. Inclined ‘arms’ support slightly curved rafters and create a portal frame effect, allowing the connections to be expressed as nodes.

16. Portal-frame effect created using inclined pinned members

6. Alternative Forms of Bracing

Nominally pin-jointed frames are braced in the vertical and horizontal directions. ‘Braced’ structures can be achieved in a variety of ways, including full-height bracing of a bay between columns, or a shorted ‘knee’ bracing to achieve hybrid action between a braced and a sway frame (as illustrated in Figure 17).

Often, the floor structure can act as ‘plan’ or horizontal bracing,but in single-storey buildings, separate horizontal bracing is required in the plane of the roof to transfer loads to the vertical bracing in the walls or cores.

6.1 Vertical Bracing

The stability of the building is dependent on the form and location of the vertical bracing, or other shear-resisting elements which are linked by floors or horizontal bracing.For simplicity, vertical bracing is located in the façade or internal separating walls. Ideally, the bracing line would be on the centre-line of the main columns, but this may conflict with the location of the inner skin of external walls. Discussion between the architect and the structural engineer at an early stage can resolve this difficulty. Often,flat steel bracing elements are located in the cavity of the masonry wall to minimise these dimensional problems.The most common arrangements of bracing in multi-storey construction is ‘X’, ‘V’ or ‘K’ bracing using steel angle or circular hollow sections (see Figure 18). Inverted ‘V’ bracing is preferred where substantial openings, e.g. doors, are required in the braced bay. To reduce its visual impact, bracing is often positioned around vertical cores, which usually house the lifts, stairs, vertical service ducts and/or toilets, or on the external face of the building within the cavity wall.

Figure 18 also illustrates the forces in the individual members.In the X-braced form, the members may be designed to resist both tension and compression, or tension only, which leads to more slender members. Tension rods or flat plates are largely ineffective in compression, and, therefore, forces are resisted only in tension when using these elements. In the K- and V-braced forms, the members must be designed to resist tension and compression, depending on the direction of the forces on the building. Tension ties are not possible in this case.

18. Different forms of bracing and their forces

Tension tie members are generally used in exposed steel work because of their apparent ‘lightness’. In X-braced frames, special brackets may be included to allow connection of the four tie members at the cross-over points. An example of an X-braced structure using CHS sections with a connecting plate is illustrated in Figure 19.

(architect : Hampshire County Council)

A ‘hybrid’ between a rigid frame and a braced frame can be achieved by the use of ‘knee’ bracing. In this case, the corner junction between a beam and column is stiffened by a short bracing member, which is designed to resist either tension or compression (see Figure 17). The bracing member transmits a force to the beam or columns, which is resisted by bending in these members. If necessary,knee bracing can be expressed as an architectural feature by curving the members or by using cast inset pieces.

6.2 Concrete or Steel Cores

As an alternative to bracing the external walls, the lift shafts and stairwells can be used as rigid ‘cores’ to stabilise the structure. Braced or steel-plated cores can be erected along with the rest of the steelwork, whereas concrete cores are generally built in advance of the frame and can be slower to construct. Accuracy is required for the installation of lift guide rails,3which is affected by the verticality and accuracy of the cores. Furthermore, multiple openings for service penetrations and doors can affect the stabilising effect of the core. It is not unusual for a large building to have more than one type of bracing system or core, depending upon the structural requirements and relative positions of the cores on plan.

built up curved rafter