Royal Festival Hall, London

|

|

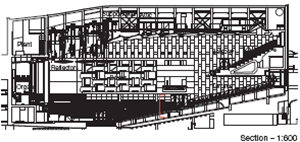

The Royal Festival Hall was the centre piece of the 1951 Festival of Britain on London’s South Bank. Its acoustics have always suffered from ‘ dryness ’ due to an excess of absorbent surfaces and performers found it difficult to hear themselves on stage because the hall is designed to project as much sound as possible away from the stage to reach the back of the vast 3000 seat space.

In a controversial refurbishment quite a bit of the interior has been altered. The walls around the stage have been re-angled and the plywood canopy removed to project less sound away from the stage. Almost all the surfaces have been altered to decrease their acoustic absorbency and increase the reverberation time.

Legroom in the stalls has been increased by 80 mm involving replacing the precast concrete step units that form the raked floor. The new units span between existing saw-tooth concrete beams, modified for the wider steps by breaking out or building up mass concrete on top of the beams. The existing carpet has been replaced with reclaimed teak strip flooring with vents in the risers for a displacement ventilation system.

The walls at the sides of the stalls, known as the Copenhagen walls are clad in knuckle-profiled elm strips, originally used in Copenhagen’s Radiohusets Concert Hall to diffuse sound. They originally had gaps between them and were mounted on a hollow studwork wall which distorted the sound. All the timber was stripped off and the existing studwork infilled with dense plasterboard. New timber profiles were made with walnut infill strips between to seal the gaps whilst maintaining a dark shadow-like appearance.

Seats were moved to make new aisles adjacent to the Copenhagen walls with new mahogany handrails that have bronze brackets with a nickel additive to give a silver finish matching the existing handrail brackets. Where the handrail meets the existing balustrade handrail at the top of the stalls the existing mahogany handrail has been cut away and re-shaped to integrate with the new rail.

According to critics the refurbishment has dramatically improved the clarity and vibrancy of the sound.

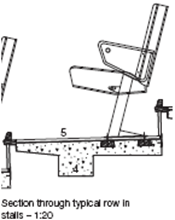

Drawing labels:

1. Side annexe floor

Existing 160 mm reinforced concrete slab retained. Existing 60 mm foamed slag screed retained. Existing carpet and felt underlay removed. 65 x 15 mm tongued and grooved teak parquet floorboards adhesive bonded to existing screed.

2. Side annexe support wall

Existing 230 mm brick walls supporting concrete slab and precast floors.

3. Raked floor to stalls

840 mm deep precast concrete step units with 200 x 200 mm integral beam spanning from masonry wall at perimeter onto existing concrete saw-tooth beams. Integral beam stopped 140 mm short of end of precast unit so that fl at underside of unit bears on saw-tooth beam. Precast units bedded on 50 mm grout with 20 mm tolerance between adjacent units.

4. Floor sub-structure

Existing 230 mm wide reinforced concrete saw-tooth beams cut back as necessary to support new precast step units. New mass concrete built up on existing beams to increase depth of each step.

5. Floor to steps and stalls

Treads formed from 65 x 15 mm tongued and grooved reclaimed teak parquet strips screwed to timber battens cast into tops of precast concrete step units. 40 x 40 x 4 mm mild steel angle fixed to front edge of precast step unit. 75 x 25 mm reclaimed teak nosing screwed to angle from underside and grooved to take tongued ends of floorboards. Risers formed from 65 x 15 mm tongued and grooved reclaimed teak parquet strips with ventilation slots to plenum beneath floor for displacement ventilation system.

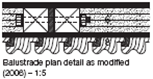

6. Balustrade structure

Existing 50 mm wide softwood carcass fixed to concrete slab and masonry walls retained. All existing timber cladding stripped off. Carcass infilled with 50 mm thick plasterboard to increase density for sound absorption.

7. Lining to stalls

9 mm elm veneered plywood backing screwed and glued to carcass. 9 mm elm veneered plywood skirting, head trim and end panel screwed and glued to backing ply.

8. Timber lining

47 x 32 mm solid elm strips with curved sound-diffusing profile screwed and glued to ply backing. 18 x 18 mm solid walnut strips screwed and glued to ply backing between elm strips to give shadow effect.

9. Lining to side annexe

9 mm elm veneered plywood panel screwed and glued to carcass.

10. Balustrade capping

Existing 95 x 25 mm solid elm capping to top and end of balustrade retained, sanded and resealed.

11. Existing handrail

Existing 305 x 57 mm mahogany handrail retained, sanded and re-sealed. Existing 95 x 10 mm mild steel stiffening plate set into underside of handrail. Existing 50 x 10 mm mild steel vertical support bolted to softwood balustrade carcass. Existing 80 x 45 mm oval profile silvered bronze sheath to vertical supports retained and polished.

12. New aisle handrail

60 x 50 mm mahogany handrail to match edge profile of existing handrail. Silvered bronze fixing brackets with 60 x 30 mm fixing plate screwed to plywood backing on balustrade.

13. Modified existing handrail

1700 mm end section of existing 305 x 57 mm mahogany handrail cut back and new mahogany piece attached to make junction with new handrail to aisle. 50 mm wide 20 mm deep finger groove in top of new handrail section.

Copenhagen wall and handrail detail section at top of stalls

Royal Festival Hall, London

Currently have 0 comments: