Richmond Olympic Oval

|

|

Chris Rudge, CEO of the Canadian Olympic Committee, did not pull any punches when comparing this building with other, more celebrated Olympic landmarks. On architect Cannon Design’s website, he declared: ‘Every visit to the Richmond Olympic Oval is awe-inspiring,’ adding that, while much has been said about the visual impact of Beijing’s National Stadium (the Bird’s Nest) and Aquatics Centre (the Water Cube) and their ‘stunning’ exteriors, interiors ‘were rather pedestrian’. By contrast, ‘the interior of the Oval is majestic’.

Creating a column-free space in which Olympic speed skaters chased record times, the structure itself became this site’s first record holder, with the world’s longest composite glulam wood/steel arches achieving a 95m span. However, what caught the attention of Trevor Boddy in his article for the AR (March 2010) was not the impressive statistics or opinions of the host city’s politicians. Rather, it was the innovative use of small-section timber, salvaged from threatened British Columbia pine. With many wood producers forced to harvest timber early due to the impact of hungry pine beetles, this impressive 2.5ha roof (built for £475 per m2) found an inventive use for the unusually large stockpiles of the humble two-by-four stud.

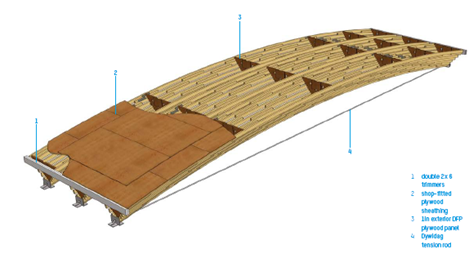

The primary structure comprises 15 arches at 14.2m centres formed by two slabs of 175 x 1,700mm glue-laminated Douglas fir wood.

Connected at the bottom with a 10mm thick stiffened steel blade. Between these are the ingenious pre-tensioned ‘wood wave’ panels that tie the arches together and give the interior its distinctive serrated character. While other infill options were considered, a US $1.5 million (£980,000) research contribution from the state government and forest industry enabled Vancouver-based engineers Fast + Epp, working with sister company StructureCraft, to offer, as managing director Paul Fast explains, ‘a unique made-in-BC solution that would also meet the wood/pine-beetle use design criteria’. Typically produced in 3.6 x 13m triple V units, held in bow-shaped form by three Dywidag tension rods, the roof’s prefabrication also included installation of acoustic and fire insulation and sprinkler branches.

In 2009, Fast + Epp won an Institution of Structural Engineers Award for its innovative ideas in the Oval, beating Arup’s design for the Bird’s Nest. Boddy says: ‘If the heavy steel members and faux-sculptural mesh of the Arup/Herzog & de Meuron design represents the architecture and economies of the decade past, the elegant green efficiency of Fast + Epp surely represent a bold direction for this new decade. [Olympic medal designer Omer] Arbel’s magnificent gold medals should go to engineers for leading the way for shunted-aside architects in North America’s greenest city.’

Southern entrance elevation during construction

The last of 450 ‘wood wave’ panels being lifted into place

Detail of the buttress-arch-wall junction on north elevation

Currently have 0 comments: