Architectural Design In Steel # Introduction

|

|

The need for guidance on detailing

Steelwork offers the opportunity for architectural expression, as well as being a structurally versatile and adaptable material. Good quality detailing is vital because it affects structural performance, cost, build ability and, perhaps most importantly, appearance.

Whilst the choice of the structural form is often the province of the structural engineer, architects should have a broad appreciation of the factors leading to the selection of the structure and its details. Traditionally, most detailing of connections is the responsibility of

the steelwork fabricator but, for exposed steelwork, detailing is of much more interest to the architect, as it impacts on the aesthetics of the structure.

In this respect it is important that designers appreciate the common fabrication and erection techniques which may exert a strong influence on the method and approach to the detailing of modern steelwork in buildings.

Connections to other materials

The attachments of other elements, such as cladding and stairs to the steel structure, are described in another series of publications. These ‘interfaces’ are crucial to the efficiency and build ability of steel framed buildings. Reference is made to good practice details in the Steel Construction Institute’s (SCI’s) publications on curtain walling,1

connections to concrete,2 and lift-shaft details.3

1. Advantages of steel construction

The distinct advantages of the use of steel in modern building construction may be summarised as follows :

• The modular nature of its fabrication (a ‘kit of parts’), which can be delivered ‘just in time’ to site when required.

• The potential for rapid erection of the framework on site, which also reduces local disruption, noise and site storage.

• It is prefabricated to a high degree of accuracy.

• Long spans can be achieved economically by a variety of structural systems in steel and composite construction, permitting greater usable space.

• Steel or composite frames are lighter than concrete frames of the same span, thus reducing foundation costs.

• Steelwork permits adaptation in the future, and components can be re-used by unbolting.

• Composite steel-concrete floors can contribute to a thermally efficient building.

• A high proportion of steel production is recycled from scrap, and all steel is recyclable.

2. Opportunity for architectural expression

Steelwork possesses various advantages for architectural expression, as follows :

• External structures clearly express their function.

• Slender members can be designed efficiently, particularly using tubular sections.

• ‘Lightness’ can be accentuated by openings in beams and by latticework in the form of trusses.

• Curved members, such as arches, can be formed easily.

• Tension structures are efficient and lightweight, particularly for long-span enclosures.

• Connections can be designed expressively.

• The fire resistance of exposed steelwork can be enhanced by the use of intumescent coatings, or by concrete or water filling (of tubular sections).

• Colours and finishes of painted steelwork can be used to great effect.

In architecture, the decision to express or conceal the structural frame, either externally or internally, is usually decided by aesthetic preference coupled with technical and functional issues. The desire to express the structure of the building is an association extending from the use of iron and early steel in the last century.

Having decided to express the structure, the architect then considers a number of design factors against which he may test his proposals. Such considerations may include architecture and functional, planning or organisational requirements, as follows.

Architectural requirements (Colour Plates 8, 13, 15, 16, 22 and 24) :

• The required overall visual effect of solidity or transparency; multiplicity of elements or minimalism; individuality or repetition of elements.

• Use of bespoke or standardised components.

• The nature of the architectural language; i.e. elegance and slenderness; strength and robustness.

• The relationship in visual and functional terms between the inside and outside spaces.

Functional requirements (Colour Plates 3, 4, 5, 9 and 27) :

• Building form and function.

• Dimensional parameters, i.e. height of building, scale, use of column-free space.

• Stability requirements (particularly for tall buildings).

• Initial cost and life-cycle cost.

• Climate; both internally and externally.

• Services provision and maintenance, and opportunities for

services integration.

• Interface details, particularly of the cladding to the frame.

• Durability, including maintenance implications and time to first maintenance.

• Fire-safety considerations.

• Health and safety requirements are now extended to Construction (Design and Maintenance) Regulations 1994 (CDM Regulations) requirements.4

• Protection from impact damage and vandalism.

Planning or organisational requirements (Colour Plates 2, 10, 11 and 23) :

• Local planning and statutory requirements, including building height, and impact of the building on the locality.

• Programme / timescale requirements, not only of the construction project, but also of the resources/demands placed on consultants.

• Agreement on the responsibilities of the architect, structural engineer and constructor.

• Client input and acceptability of the design concept.

• Availability of suitable resources for construction, and opportunities for prefabrication (e.g. on a remote site).

Excellent examples from the 1980s showed what could be achieved in the expressive use of steel. In the Sainsbury Centre, a simple portal-frame structure was proposed initially, but rejected in favour of the deeper and more highly articulated structural frame that

was finally adopted (see Figure 1.1).

The highly perforated structural members of the Renault Parts Distribution Centre (Figure 1.2) are an ‘architectural’ expression of engineering and technological efficiency, yet they do not necessarily represent the most efficient structural solution. These are conceptual

issues in which both the structural engineer and the architect should share a close interest, and which must be resolved jointly at the early stages of design. However, many examples of exposed steel follow a much more straightforward approach (see Colour Plate 26).

1.1 Portal-frame structure used in the Sainsbury Centre, Norwich (architect: Foster and Partners)

3. Holistic approach

To achieve economic and practical architectural details, there has to be a basic appreciation of the performance of the overall structure itself and the loading conditions imposed on the member or component in question. The form of the structure will strongly

influence the details employed.

For the architect, details often evolve through the logical stages of conceptual design, followed by further rationalisation into the detailed design, i.e. from the macro to the micro. The architect may approach the concept design with the key component details already in mind. However, the final solution will be influenced by structural issues, an understanding of the fabrication and construction process, and other functional constraints (see Colour Plate 14).

As one of the first examples of external support using masts and cables, the steelwork for the Renault Parts Distribution Centre (see Figure 1.2) was subject to considerable refinement at the design stage by computer analysis, and the components were finally rigorously tested to assess their load capacity. The ‘mast and arm’ details reached a high level of sophistication, creating a strong aesthetic and functional appeal for what could have been a bland enclosure.

1.2 The Renault Parts Distribution Centre, Swindon, showing mast and tension structure (architect: Foster and Partners)

4. Scale and ornament

4.1 Scale

Buildings should be designed well at a range of scales. An understanding and an appreciation of all the scales will help in the art of assembly and detailing. Therefore, an elegant and well proportioned building will have been successfully considered at the large scale as well as in its details. Good details alone do not necessarily lead to architectural success. This achievement relies on the consideration of all elements of the composition of varying scale(see Colour Plates 14 and 20).

For example, the canopy of the pavilion building contrasts and compliments the monumental scale of the Millennium Dome, as illustrated in Figure 1.3.

Examples of the order of scale are as follows :

1. Volumetric scale: The big picture for the whole project and its locality.

2. Structural scale: The structural system, e.g. a 40 m span roof structure.

3. Module scale: A column grid, say, of 9 m.

4. Elemental scale: Repetitive elements, such as beams.

5. Assembly scale: The form of the connections.

6. Detail scale: The detail of the base of a column, or part of a truss.

7. Textural scale: Surface appearance.

8. Point scale: For example, the head of an individual bolt on a plate.

All of these elements of scale represent opportunities for architectural expression.

1.3 Pavilion at the Millennium Dome, Greenwich, UK (architect: Richard Rogers Partnership)

4.2 Ornament

In architectural composition, ornament has traditionally been sought in those places where portions of the building change significantly from one part to another, whether it be from wall to roof, wall to ceiling, one structural element to another, i.e. beam to column, or column to ground, and so on (see Colour Plates 9 and 27).

Much of the ornament and articulation of parts established in twentieth-century architecture has been found in the attention to the junctions between prefabricated components, whether they be parts of the structure or of the cladding systems. Consequently, in steel framed buildings where the structure is exposed, ornament is usually sought in the connections between structural members and between the elements which comprise them (see Colour Plate 19). The careful shaping of the connection plates, stiffening elements, bolting and welding patterns, hubs for diagonal bracing and tie-rod assemblies, have taken on an important role, which is not only structural but also gives expression to the functionality of construction.

Examples where attention to detail can be used to provide ornamentation to an otherwise plain structure are :

• articulated attachment of horizontal and vertical members (Figure 1.2 and Colour Plates 12, 25 and 26)

• supports to arched members (i.e. at foundations) (Figures 1.3 and 1.4)

• suspension and bracing members, including tie rods (Figure 1.5 and Colour Plate 11)

• tie members that counterbalance a long-span portal frame (Figure 1.6)

• connections within trusses (Figure 1.7 and Colour Plate 20)

• fabricated beams or stiffened members (Figure 1.8 and Colour Plate 19)

1.4 Thames Valley University, pinjointed connections supporting curve darched steel members (architect: Richard Rogers Partnership)

1.5 Dynamic Earth Centre, Edinburgh (architect : Michael Hopkins & Partners)

1.6 St Paul’s Girls School (architect: Faulkner Browns)

1.7 Inland Revenue Headquarters, Nottingham, showing truss details which provide interest and articulation (architect : Michael Hopkins and Partners)

1.8 Operations Centre at Waterloo, London, showing a fabricated cantilever beam supporting a walkway (architect : Nicholas Grimshaw & Partners)

1.9 Orange Operational Facility, Darlington (architect : Nicholas Grimshaw & Partners)

1.10 Support to fabric roof at the Imagination Building, London (architect : Ron Herron and Partners)

• mullions with multiple perforations (Figure 1.9)

• support to a fabric roof (Figure 1.10 and Colour Plate 19).

Relationships can be established between the individual parts and the overall building form, which have a basis in elementary structuralaction.

5. Steel ‘kit of parts’

A wide range of steel components is available to the architect and designer from:

• hot-rolled sections, such as I, H and L shapes

• tubular sections of circular, square and rectangular shape

• fabricated sections made by welding

• light steel components made from strip steel

• stainless steel components

• modular units made from light steel components.

This book concentrates on the application of hot-rolled and tubular-steel structures, but the principles are applicable to a ‘kit of parts’ of steel components. Indeed, in many buildings, I-sections are used for beams, H-sections for columns, tubular sections for bracing, fabricated sections for primary beams or transfer beams supporting columns, light steel for infill walls, and modular elements for plant rooms and toilets. Site connections are usually made by bolting, although welded connections may be preferred for factory-made connections.

More information on the technical characteristics of steel is presented in Chapter 11.

5.1 Hot-rolled steel sections

A wide range of standard steel sections is produced by hot rolling, from which designers can select the profile, size and weight appropriate to the particular application. Table 1.1 illustrates the range of ‘open’ sections used in the UK, which are universal beam (UB), universal column (UC), parallel flange channel (PFC) and angle sections.

In continental Europe, IPE and HE sections are generally used rather than UB and UC sections. In the USA, W and WF sections are used (which are similar to UB and UC sections).

Modern steel sections have parallel flanges. Also, parallel flange channels largely replace channels with tapered flanges. The ‘serial size’ refers to the designated section depth and width in which there are a range of weights of section. However, it should be noted that the UB or UC section designation, such as 406 × 140 × 39 kg/m refers to the approximate depth, width and weight, and exact dimensions should be obtained from standard tables.

Table 1.1 Standard hot-rolled sections (UB, UC, and L)

| Universal beam (UB) | Universal Beams |

| Nominal dimensions (mm) | |

| D B |

| Universal beam (UC)  | Universal Columns D B 152 152 203 203 254 254 305 305 356 368 and 406 |

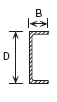

| Channel (PFC) | Parallel Flange Channel D B 100 50 125 65 150 75 and 90 180 75 and 90 200 75 and 90 230 75 and 90 260 75 and 90 300 90 and 100 380 100 430 100 |

| Equal angle | Rolled Steel Angles External dimension of equal angle: 25, 30, 40, 45, 50 60, 70, 80, 90, 100 120, 150, 200, 250 |

| Unequal angle | Rolled Steel Angles External dimension of unequal angle Various sizes from : 40 × 25 to 200 × 150 Including common sizes of : 75 × 50, 100 × 75, 150 × 75, 200 × 100 |

Table 1.2 Typical proportion of cost and man-hours per tonne in steel fabrication in buildings

| Item | Man-hours per tonne | Total % of cost |

| Materials production Fabrication Erection Protective treatment | 3–4 | 30 |

| Total | 14–22 | 100 |

The serial size of UBs and UCs varies in increments of approximately 50 mm depth for the shallower sections, and 75 mm for the deeper sections. Within each serial size, the designer maychoose from a number of different sections of similar height. The standardisation of steel sections has also led to the adoption of standard connections, which have become familiar within the industry.5,6

Table 1.2 shows the breakdown of costs in a typical framework of a building. It is apparent that only 30% of the cost associated with a steel frame relates to the material itself. Costs can increase significantly if fabrication and detailing create a demand for increased labour time. For example, using a heavier steel section is generally cheaper than using a lighter section that has to be stiffened at its connections.

1.6 Tubular steelwork

The use of tubular steelwork creates a wide range of architectural opportunities in internal or external applications. The word ‘tubular’ has come to mean applications using all forms of structural hollow sections, rather than just circular sections. Tubular sections are available as circular hollow sections (CHS), and square or rectangular hollow sections (SHS and RHS, respectively). Oval tubes are also available. SHS can also be used as the generic title ‘structural hollow sections’. More detail on the methods of manufacture is presented in Section 11.3.

Table 1.3 defines the common section sizes. All tubular sections have exact external dimensions for detailing purposes.

The factors that influence the use of tubular construction are their :

• aesthetic appeal, which is often due to their apparent lightness of the members

• reduced weight of steel due to their structural efficiency,depending on their application

• torsional resistance (hollow sections are particularly good at resisting torsional effects due to eccentric loading)

• compression resistance for use as columns or bracing members(tubular sections are very efficient in compression due to their reduced slenderness in buckling conditions)

Table 1.3 Structural hollow sections (note, external dimensions are constant for a given serial size in all hollow sections)

• bending resistance of slender sections (if a beam is unrestrained throughout its length, the tubular section can be more efficient than a conventional I-section)

• efficiency under combined bending and torsion, such as instructures curved on plan

• fire and corrosion protection costs (which are reduced because of the low surface area of the tubular section)

• ease of site assembly, as also influenced by requirements forwelding

• availability in higher grade S355 steel.

Fabricators cost all the steel-related items accurately, but the cost of fire and corrosion protection would normally be estimated separately. Some fabricators are specialists in tubular construction and can advise on costs and details at the planning stage. Additional aspects, such as the grinding of welds and special connection details,should be identified at this stage.

When using larger CHS, for example in long-span trusses, it is important to identify fabricators with specialist profiling equipment who can make the connections between the chords and web-members efficiently. This is particularly important for more complex assemblies, such as triangular lattice girders, which require a greater amount of fabrication effort and skill (see Section 6.8). The alternative may be to use SHS, which only require cutting the ends of the chord members at the correct angle, rather than profiling the cut ends.

The Waterloo International Terminal by Nicholas Grimshaw and Partners gains most of its visual impact by its striking light weight roof. The roof consists of a series of tubular trusses supporting stainless steel cladding and glazing. Every truss is different, but considerable economy and simplification was achieved by repetition of the same external dimensions of the tubular sections(see Figure 1.11).

The excellent torsional resistance and stiffness of tubular sections(often ten times greater than that of I-sections of equivalent area),makes them suitable for curved bridges and canopies where members curve on plan and possibly also on elevation (see Colour Plate 14). Architects such as Santiago Calatrava have utilised this property by creating tubular spine-beams and inclined arches that resist eccentric loading in bending and torsion. An excellent example of the use of tubular-inclined arches is in the Millennium Bridge,Gates head (Colour Plate 16).

Transportation buildings have also exploited the qualities of tubular construction. Examples include Stansted and Stuttgart Airports (see Figure 1.12 and Colour Plate 9, and also see Colour Plate 7). One ofthe largest buildings in the world employing tubular steel is the International Airport at Kansai, Japan, designed by Renzo Piano (seeFigure 1.13).

Tubular structures are not only reserved for large projects. The lightness of tubular members is emphasised at the ‘Gateway’ in Peckham, London (see Colour Plate 10). Similarly, the inclined tubular members created a curved appearance in Hodder Associates’ enclosed pedestrian footbridge in Manchester (see Colour Plate 17).

1.12 Stuttgart Airport Roof using tubular column ‘trees’—see also Colour Plate 9 (architect: Von Gerkan Marg &Partners)

1.13 Tubular trusses at Kansai Airport, Japan (architect: Renzo Piano Workshop)

6. Fabricated sections

Fabricated steel sections are produced by welding steel plates in a factory process. These sections are fabricated to the required geometry and are not standard sections. They are usually economic where :

• the section size can be ‘tailor-made’ to the particular application and member depth

• long-span primary beams would not be achievable using hot-rolled sections

• heavy ‘transfer’ or podium structures are required to support columns or other heavy loads

• asymmetric sections are more efficient than standard sections

• tapered sections are specified, e.g. in grandstand canopies

• curved members are created by cutting the web and bending the flange into a curve of the required radius.

The use of fabricated sections in a floor grillage is presented in Section 4.2. The primary practical consideration is the availability of standard plate sizes and the relative thicknesses of the plates used in the flanges and web of the section. Examples of the use of fabricated members are also illustrated in Section 2.4.

6.2 Cold-formed sections

A variety of cold-formed sections (CFSs) are produced and these sections are widely used as secondary members, such as purlins, or in light steel framing for primary structural applications. Typical C sections are illustrated in Table 1.4. CFSs are produced by cold rolling from galvanized strip steel in thicknesses of 1.2 to 3.2 mm for structural applications. Various SCI publications, including an Architect’s Guide,6describe the use of cold-formed steel sections and light steel framing in building.

Table 1.4 Cold-formed sections (produced by various manufacturers)

| Standard C and Z sections

| Depth of C or Z sections (typical) (mm) : 75, 100, 125, 140, 170 200, 240, 300 |

| Modified C and Z sections

| Steel thickness (typical) (mm) : 1.2, 1.6, 1.8, 2.0, 2.4, 3.2 |

Cold-formed steel sections can be used as :

• infill or separating walls in steel framed buildings

• floor joists and secondary members in frames

• light steel framing, erected as storey high wall-panels, in housing and residential buildings

• purlins in roofs and in over-roofing in building renovation

• modular units in cellular building forms, such as hotels and student residences

• cladding support members and over-cladding in building renovation.

Steel decking is produced in steel thicknesses from 0.9 to 1.25 mm,and is available in two generic forms :

• deck profiles of 45 to 80 mm depth for use in composite construction

• deep deck profiles of 210 or 225 mm depth for use in Slim dek construction.

These applications in composite construction are covered in more detail in Section 4.1.

6.3 Modular construction

Modular construction uses prefabricated ‘volumetric’ components which are generally made from light steel-frames, although they often incorporate SHS columns for the corner ‘posts’. It is most economic where the modules can be manufactured repetitively to achieve ‘economy of scale’, and where the dimensions of the modules are suitable for transportation and installation (3.0 to 4.2 mare typical module widths).

The Peabody Trust’s Murray Grove project in London achieved architectural acclaim by being the first major use of modular construction in the social-housing sector (see Figure 1.4). The modular nature of the building was softened by using prefabricated balconies, access walkways, and a ‘core’ lift and stairs structure at the axis of the two wings of the building.

More guidance on the use of modular construction can be found in recent SCI publications.7,8. Modular units can be used in more regular framed structures in the form of prefabricated plant rooms,‘clean rooms’, bathrooms and toilets, which are often lifted or slid into place on the floor.

1.14 Modular construction of social housing in London for the Peabody Trust

(architect: Cartwright Pickard Architects)

Your post on architectural design in steel was insightful—I find the use of different materials in architecture fascinating. By the way, if you're ever looking for architects in Swindon, I recently came across a website that might be helpful: https://www.philipshell.co.uk/. Thanks for sharing your thoughts on steel in architectural design, and I thought you and your readers might find this Architects Swindon resource quite valuable!

good info