Working with Aluminum (Part 1)

|

|

Now that you’ve heard about aluminum, you may want to know what it looks like. We’ll describe it, beginning with the forms in which it is produced, how these forms are shaped and altered to become structural components, and how these components can be dressed up with coatings. We will include some comments on how this process differs from the preparation of steel for duty and will conclude with a few suggestions on how to put the structural components in to place. This chapter, then, presents the product forms in which aluminum is most commonly used for structural components, and how these product forms are fabricated and erected.

1. PRODUCT FORMS

The forms of aluminum used in structural components include extrusions, flat-rolled products, castings, and forgings. The most widely used of these forms are extrusions and the flat-rolled products, sheet and plate. Castings typically have less reliable properties than the wrought product forms, and forgings are often more expensive to produce than other wrought forms. Castings and forgings do, however, lend themselves to more complex shapes than extrusions and flat-rolled products.

1.1 Extrusions

Introduction What do aluminum and Play-Doh have in common? They can both be extruded, of course (Figure 1). Extrusions are produced by pushing solid material through an opening called a die to form parts with complex cross sections. Aluminum is not the only metal fabricated this way, but it is the most readily and commonly extruded. (Stainless steel can also be extruded, but it requires such great pressures that only small and simple stainless shapes can be made). The extrusion process makes aluminum an extremely versatile material for structural design. Rather than being limited to the standard rolled shapes, designers can concoct their own cross sections, putting material where it is needed. Solid and hollow cross sections, even sections with multiple hollows, can be readily extruded (Figure 2).

Figure 1. Engineer of the future extruding a Play-Doh I-beam. (Play-Doh is a

registered trademark of Kenner.)

Figure 2. Examples of complex extruded shapes. (Courtesy of Cardinal Aluminum

Co.)

While extrusions dominate applications for parts with a constant cross section, bar and rod are also produced by rolling, and tubes and wire by drawing, a process by which material is pulled (as opposed to pushed) through a die to change the cross section or harden the material. Cold-finishing may be used to improve surface finish and dimensional tolerances. Sometimes a combination of methods is used; for example, tube may be extruded and then drawn; bar may be rolled and then cold-finished. Products that have been cold-finished or drawn are held to tighter tolerances on cross-sectional dimensions than extruded products.

Standard Extruded Shapes Before World War II, most aluminum shapes were produced by rolling, like steel, and so had cross sections similar to those of steel. Many of these shapes had sloped flanges that facilitated rolling but complicated connection details. Wartime and postwar demand for aluminum products prompted better production techniques, especially extrusions, which eventually displaced much of the rolled production. Since extrusions are not subject to the limitations of the rolling process, the need for sloped flanges was gone. Extrusions continued to be produced in shapes that looked like rolled products, however, because these shapes were standard. Around 1970

the Aluminum Association introduced standard channel and I-beam shapes designed to be extruded, with constant thickness flanges and optimum dimensions for strength (Figure 3). Today, almost no aluminum shapes are produced by rolling. Many of the old cross sections suited to production by rolling are still shown in catalogs, however, even though today they are extruded, not rolled.

Figure 3. Rolled shape with sloped flanges, and extruded shape with constant thickness

flanges.

A number of common extruded shapes are shown in extruders’ catalogs. Some of these shapes, as well as the Aluminum Association standard shapes, are included among those listed in the Aluminum Design Manual, Part VI, Section Properties. Extruders usually maintain an inventory of dies. Some are proprietary and, thus, are for the exclusive use of a particular customer; others are called open dies, and these are the shapes shown in catalogs and available to any paying customer.

The Aluminum Association has established standard extruded I-beam and channel shapes, as mentioned above, in depths from 2 to 12 in. (They are not available in hard metric sizes.) These sections are efficient for structural applications and are produced by a number of extruders. Appendix B contains dimensions and section properties for these shapes, called Aluminum Association standard channels and I beams. Design data for these shapes is given in Appendices D and E.

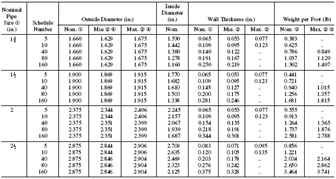

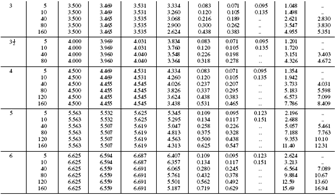

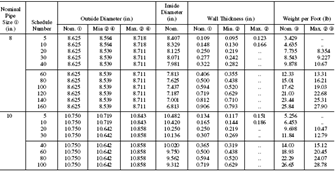

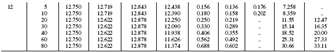

Aluminum pipe, with the same dimensions as steel pipe of the same nominal size and schedule, is also extruded, in diameters up to 12 in. Dimensions and section properties are listed in Table 1. Aluminum pipe is usually 6061-T6 alloy, but it is also produced in 3003-H18 (but only under 1 in. nominal pipe size), 3003-H112, and 6063-T6.

Custom Extruded Shapes Sometimes the Aluminum Association or other standard shapes are impractical or inefficient for a specific application. In these cases, users may design their own shapes. Keep in mind that some limitations exist :

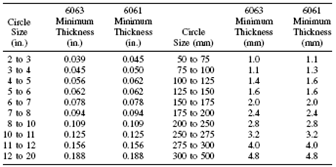

1) Minimum Thickness: The minimum thickness is a function of a number of factors, including the circle size (larger shapes require larger wall thickness) and whether a shape is hollow or solid. Table 2. provides approximate guidelines, but actual limits depend on the shape and the extruder. Elongation testing is not performed for shapes less than 0.062 in. [1.6 mm] thick.

2) Maximum Length: Extrusions can be produced up to 100 ft [30 m] long, but 40 ft [12 m] is generally the practical limit for extrusions shipped by truck. Structural shapes available from metal supply warehouses usually are stocked in 20 ft or 25 ft [6 m or 7.5 m] maximum lengths.

3) Maximum Circle Size: Extrusions are produced from billets, which are usually cylindrically shaped. Because of this, extrusion cross-section size is usually limited to that which fits within a circle. Larger extrusion presses use larger circle size dies. There are numerous 10 in. [250 mm] and smaller presses, about a dozen mills with presses larger than 12 in. [300 mm], while the largest in North America is 31 in. [790 mm]. Because of production limitations, an extrusion typically cannot fill the full area of the circle, but rather only part of the circle area (Figure 4).

4) Maximum Area: The largest cross-sectional area that can be extruded is about 125 in2 [80,600 mm2].

5) Maximum Weight: The maximum total weight of an extrusion is limited by the weight of a billet to about 4,300 lb [2,000 kg].

TABLE 1. Diameters,Wall Thicknesses,Weights—Pipe(continued)

TABLE 1. Diameters, Wall Thicknesses, Weights—Pipe (continued)

➀ In accordance with ANSI/ASME Standards B36.10M and B36.19M.

➁ Based on standard tolerances for pipe .

➂ Based on nominal dimensions, plain ends, and a density of 0.098 lb per cu in., the density of 6061 alloy. For alloy 6063, multiply by 0.99, and for alloy 3003 multiply by 1.011.

④ For schedules 5 and 10, these values apply to mean outside diameters.$

TABLE 2a. Approximate Minimum Thicknesses for 6061 and 6063

Solid Extrusions

TABLE 2b. Approximate Minimum Thicknesses for 6061 and 6063

Hollow Extrusions

Figure 4. Useable portion of an extrusion circle size. Extrusion profiles must generally

fit within the area indicated by the dotted line

We specialize in trading and exporting various grades of ferrous, non-ferrous metal, plastic and paper scrap, at Ivory Phar Inc, we are leading Aluminum Scrap Supplier. We offer a reliable supply of diverse aluminum scrap types, including Extrusion 6063, UBC (Used Beverage Cans), Wheel Scrap, and Engine Scrap. Our commitment to quality ensures that each material meets industry standards, making us the preferred choice for companies dedicated to sustainable recycling.